#704,No.2362,Fangzhong Road,Xiamen,Fujian,China,361009 +86-13860439542 [email protected]

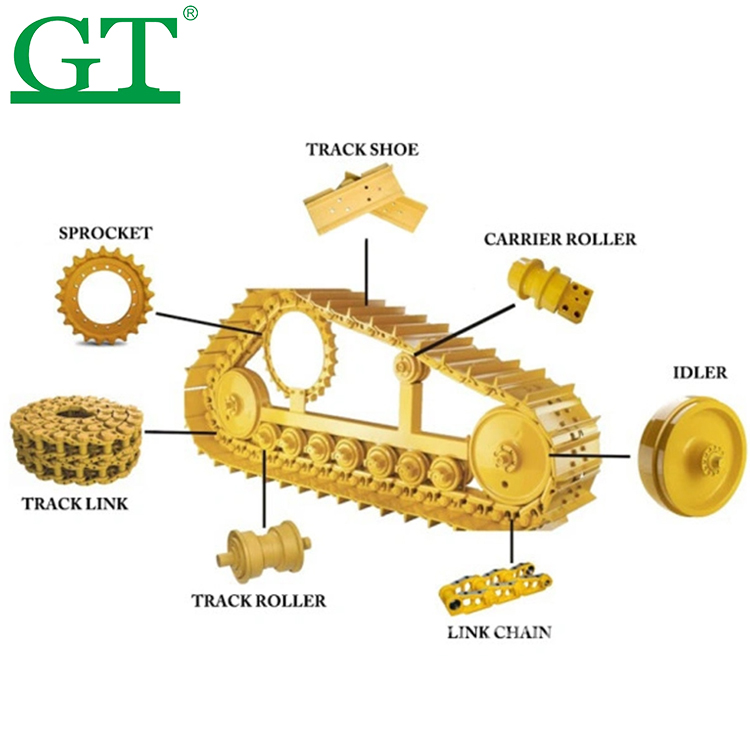

Our dozer track components are the key system to support the full working conditions of the equipment, including track chains, carrier wheels, supporting wheels, guide wheels, drive teeth and other complete components, which are suitable for 60+ models such as Caterpillar D5-D11, Komatsu D51-D155, John Deere 650K-950K and so on, and can be precisely matched with the equipment, ranging from municipal earthmoving to heavy-duty mining. It can be matched accurately from municipal earthmoving to mining heavy-duty.

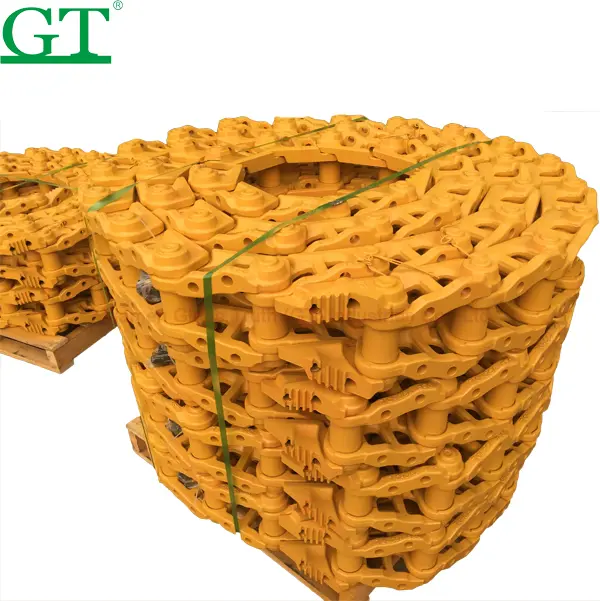

The core components adopt advanced technology: the track links are forged with 40CrNiMo alloy, and the surface is laser coated with wear-resistant layer with a thickness of 3mm, which improves the wear-resistant ability by 50% compared with the ordinary model; the body of the carrier wheel and the supporting wheel is QT700 ductile cast iron, and the bearings are made of double rows of tapered roller structure, which, together with the triple Viton oil seals, can work continuously in 1.5 meters deep mud and water under the waterproof grade of IP68; the drive teeth are made of high frequency and high speed, which are made of high quality. The gear surface of the drive teeth is quenched by high-frequency, with a hardness of HRC60, and the meshing gap with the track link is controlled within 0.1mm to avoid impact noise.

Optimized for extreme scenarios: the spacing error of the chain links of the mining model is ≤0.05mm, which can withstand 20 tons of instantaneous impact force when adapted to Carter D9; all bearings of the cold zone model are filled with -40℃ low-temperature grease, which ensures that the John Deere 850K starts to run at -35℃; the wetland model is fitted with an anti-mud ring on the guide pulley, which reduces the amount of mud and sand adhering to it by 70% when adapted to the Komatsu D65.

The whole set of components is produced according to the original installation standard, and can be installed directly without adjustment. After replacing the Volvo SD160 components in an engineering team, two people completed the installation in 6 hours, and the traction efficiency of the equipment was increased by 12%, and the maintenance cycle of the crawler system was extended from 4 to 9 months, which lowered the comprehensive operation cost by 35%.