#704,No.2362,Fangzhong Road,Xiamen,Fujian,China,361009 +86-13860439542 [email protected]

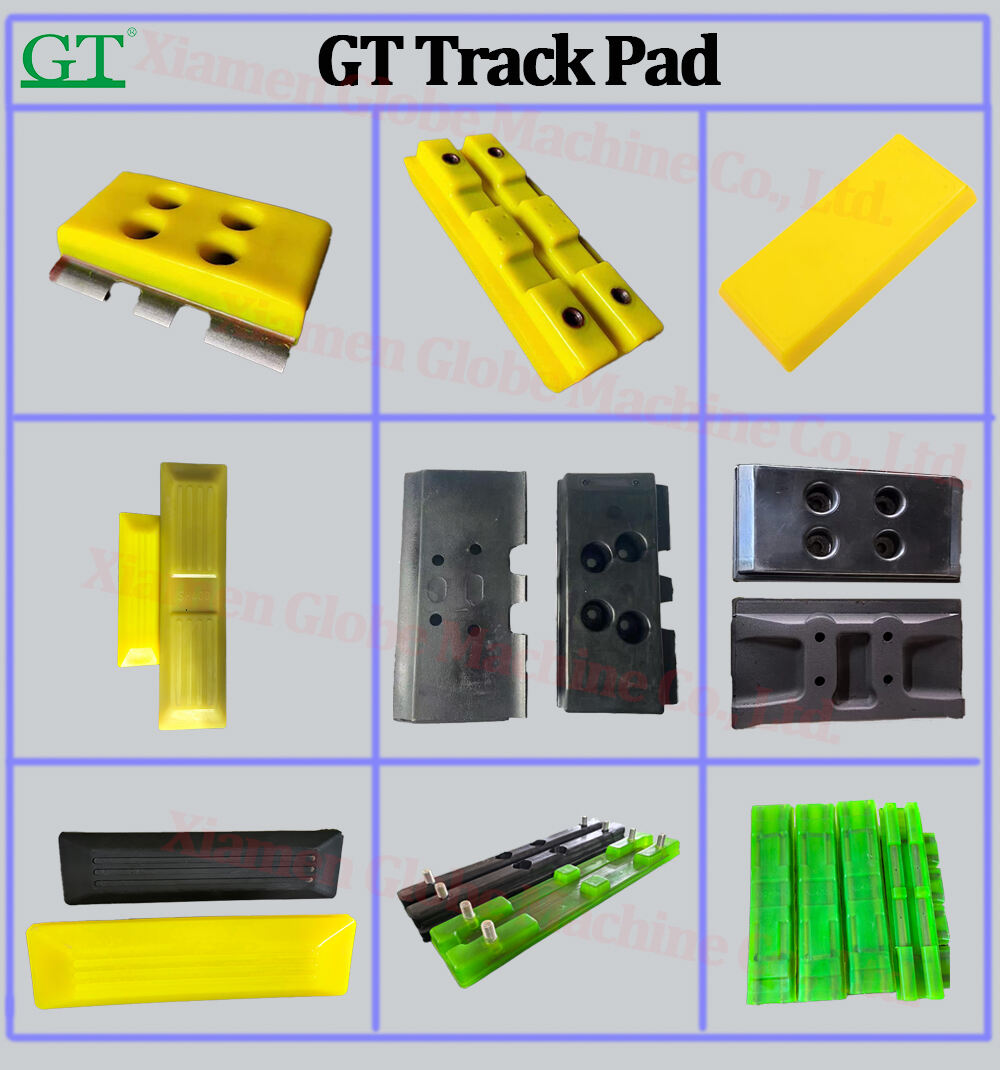

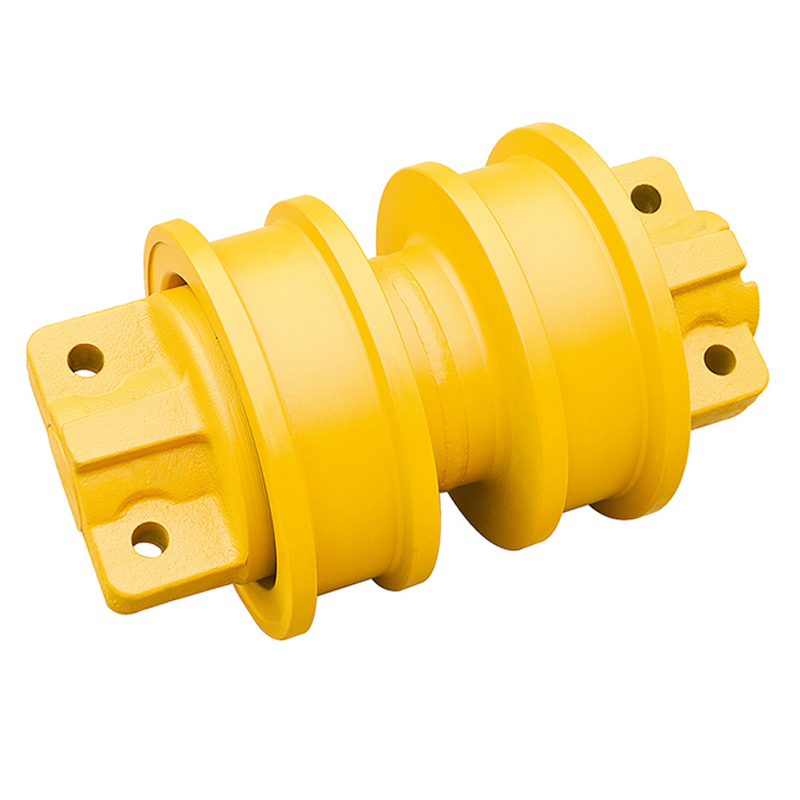

Our undercarriage parts for dozers cover a full range of core parts such as track chains, supporting wheels, guide wheels, drive wheels, etc. They are accurately adapted to the mainstream models such as Caterpillar D5-D9, Komatsu D51-D155, John Deere 650K-850K, etc. They are made of high-purity alloy steel through forging and molding, and the key parts are strengthened by medium frequency quenching with a surface hardness of HRC55-60. Adopting high-purity alloy steel by forging and molding, the key parts are strengthened by mid-frequency quenching, and the surface hardness is up to HRC55-60. In extreme scenes such as mine rubble field, muddy wetland, desert Gobi, etc., the wear-resistant performance is upgraded by 40% compared with the common parts, and the service life of track links can reach more than 1200 hours.

For different operating environments, the parts have been optimized: the mining model increases the chain pin diameter by 3mm, and the tensile strength is increased to 1800MPa; the wetland model adopts Viton sealing ring, with waterproof level up to IP68, and can be immersed for 48 hours without leakage; the cold model chooses the low-temperature toughness steel, which maintains good ductility and avoids brittleness cracking at -30°C. All the parts are strictly in accordance with the original tolerance of the manufacturer. All components are manufactured in strict accordance with the original tolerance standards, no need to adjust the hole position during installation, and a single set of replacement can be completed in 30 minutes by an ordinary maintenance team, significantly reducing downtime.Whether it's high-frequency work in building construction or complex terrain in agricultural renovation, these parts can reduce unscheduled maintenance by 70%, helping the equipment to continue to deliver stable power.