Fahamka Walaalka Qoraxda ee Buldooserka Wajibka iyo Xaaladaha Arrinta Badan

Qaabka iyo Wajibka Walaalka Walaalka Qoraxda ee Buldooserka Nidaamka Hoose ee Walaalka

Cagaaqa soo saar ee jiidada waa isticmaalka badan ee qaab soo saar ee jiidada oo dhan ee qaab soo saar kasta oo leh midabka, ka qaadaya saddex bogoo ka mid ah wadkii eejiyaha ayaa jiidada ayaa soo saaraya jiidada soo saar ee ka hor inta lagu dhaafay. Qaab soo saar kasta waxaa ka mid ah xawaaridka badan ee fudud oo ka soo tsugan, waxyaabaha dhaafsan oo dhan, sidoo kale midabka guriga oo leh suuqda oo leh jiidada. Tallaabada ayaa ka caawinaya in la qaybiyo xoogga ee jiidada ee jiidada ee ay ku jirtan tahay. Waxaa sidoo kale jira kanaladaha dhexdeeda ee laa iyo laa soo saar, taadna ka qaybi doonaa xidhiidhka midabka ee fudud. Tan waxay kala saaraya in la soo saar xoogga oo joogto leh oo kala saaraya waqtiga ee la soo saar midabka. Rappornimada ee dhaqanka ee ka soo tsugan ee 2023, saxda ugu yara ee tallaabada waxaa ka caawinaya in la soo saar jiidada ee la soo saar.

Tallafalka ee Flange ee kow iyo laba Cagaaqa soo saar ee jiidada ee jiidada ee jiidada Codsiyada

| Nooca Flange | Qorshahoodda Cadaabka | Isticmaalka Saxda ah |

|---|---|---|

| Flange ee kow | Qaabka ee jiidada ee jiidada ee jiidada | Makinaarrada dhibaato ee qalal |

| Labada dhulka | Khadka horizontalka ee dhaafalka/dhulka aan isku halayn | Bulldozers iyo makinaarrada dhulka |

| Rollers laba dhulka waxay ugu badaneyaan jirka 20-30% ee jirka dhexeeya ee kuwa xajmiga ugu badanayd in ay dhiman karaan track-ka. Modyooyinka single-flange waxay bixisaa xawaalid iyo jumlada dhaqan ee korantayd ee ku yaabka ama jirka dhaqan ee dhisidda. |

Sidee Ballaadhka Track-ka iyo Ballaadhka Carrida Igu Differa Dheeraadka iyo Calaamadda

Haddii kaleba ay ka caawinaan karti track-ka, ballaadhka carrida waxay leeyihiin qaybo qurxana iyo khaasida khaadka verticaal. Ballaadhka track-ka ee bulldozer iyo makinaarrada waxay leeyihiin qaybooyinka farsan iyo dhulka laa doortay si ay ugu badalayn karaan xawaalada radial ee jirka, xawaalada axial wakhtiga dhaafalka ay dhacdo, iyo xawaalada shock ee ka soo dhaafay dhulka xoog badan.

Nidaamyada caadiga ah ee dhiman iyo natiijadaha mekhaaniska ee ka soo dhaafay ballaadhka track-ka oo la yidhaahdo

Hantida 2024 ee deegaanka waxay ka aqoonsatay in 68% ee dhiman khaadka ka soo dhaafay ballaadhka track-ka, badanaa sababtaa:

- Bearing seizure : Waxay daboolka kartaa horumarka track-ka iyo si joogto ah ay korontaa sprocket

- Tuxaansho ee flange : Waxay badbaadijiraa habka laa tuxaansho iyo dhaqsho

- Tuxaansho ee axle : Waxay kala qaadiso qaabka laa 40% oo xadgudbi jawaahir la xiriira

- Dhaafasho ee grease : Dhuulka birta waxay badbaadijiraa turjumaadka 300%, taadna waxay keenaa jirrada badan ee meesha metal

Tuxaansho ee roller la soo saari karo waxay u dhici laa in ay qorshayn doonto halbeegooda iyo waxay kala qaadiso kharja ee motor ee 18% sababta wadarta xadgudbinta.

Soo saarida Alamaadaha Tuxaansho iyo Sameynada Inspekshanka Qayarka Hoose

Alamaadaha muhimka ah ee tuxaansho ee roller trackiga ku jira dozer iyo nimaan models

Oogatooyinka waa inay la raadgaliyaan tuxaansho ee track la isku halgali, dhaafasho aan la xirin, khatarada meesha loo yaqaan metallic, iyo kala duwanaansho ee laa maareyn. Tuxaansho ee flange laa ilaaliyay in ay fududaan 5-7mm ee kor ugu badan waxay muujin doontaa tuxaansho dheer. Soo saarida hore waxay muhim baa leeyihiin, sida 68% ee qayarka laa trackiga soo jeediyay ayaa loo muujiyay in ay leeyihiin ballan oo ku xadhahan roller marka horay ay qayarka hoose ee laa tuxaansho (taasoo ah 2023 ee undercarriage analysis).

Tegniyada falanka iyo xajinta qaabka xidhka ee Track Rollers

Falanqeynta caasimada waxay la koobiyaan saddex tariiqo:

- Qiimaya dib u eeg : Raad furrow, pitting, ama habka la xiriira aan isku mid ahayn

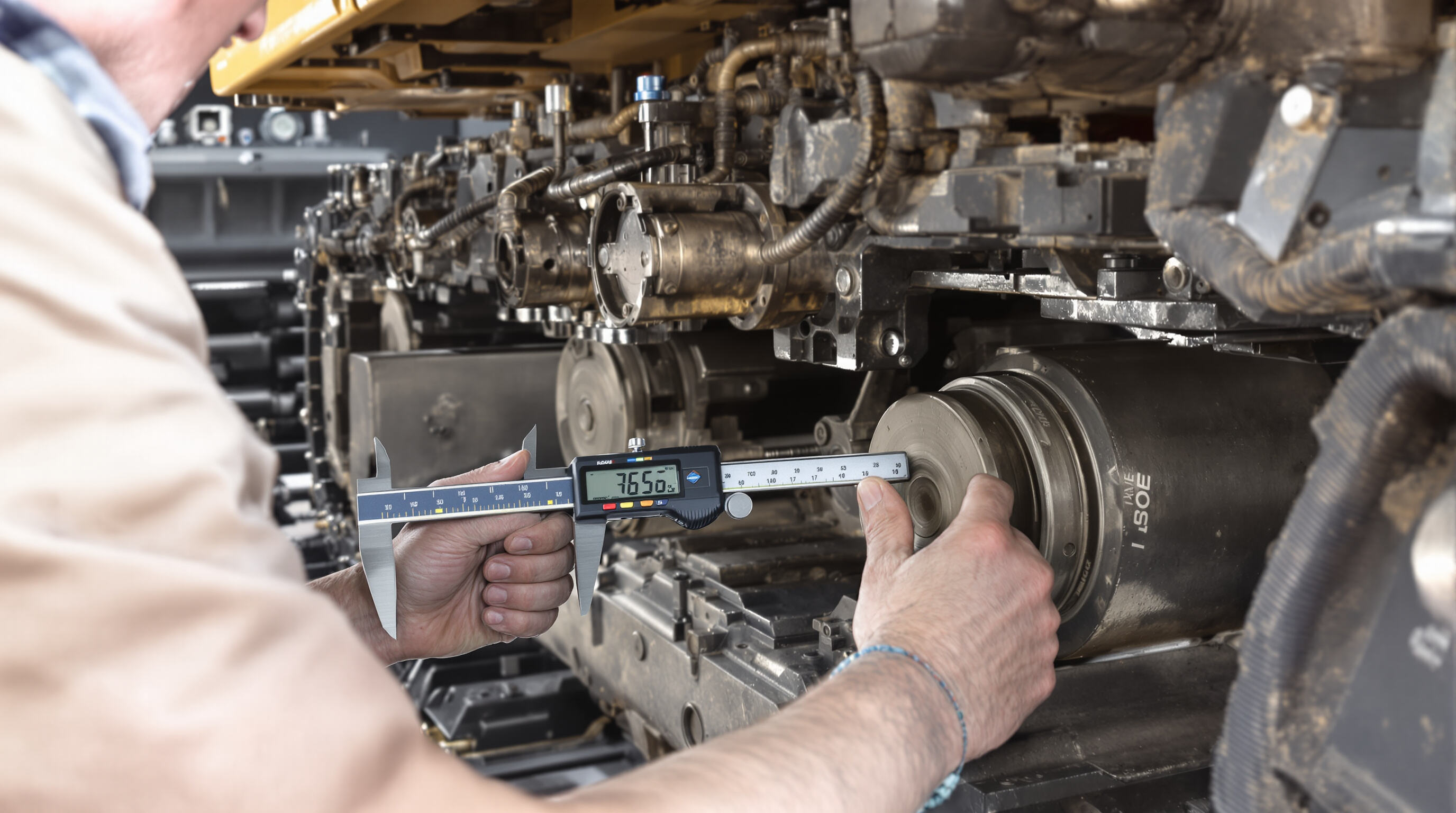

- Xajinta qaabka : Qaybi qaabka flange iyo xajinta qabiya roller-ka oo loo isticmaayo calipers iyadoo la raacayo tijaabada OEM

- Tijaabada ammaanka : Xidh roller-ka si joogto ah in la hubiyo dhibaatooyinka ama xidhiidhka

Beddel qalabka marka xidhka ka weyn 10% ee qaybaha hore. Dheeraad ah eeg tijaabada xidhka ee qalabka Manufacturer ee Track Roller ee Bulldozer Excavator models.

Xajinta axta iyo qalabka la xiriira ee dhexdooda ee dhibaatooyinka labaad

Isticmaal bore gauge si aad uga saabsan kartid axle seats ee scoring ama ovalization—distortions ka yar 0.5mm waxay noqon kartaa in ay dambe waligeed roller wear. Shaqshaqiya khaasida soo baxsan:

- Sprocket teeth ee hooking (beddel haddii ay wear ≥4mm)

- Idler wheels ee rim deformation

- Track links ee bushing wear ka weyn 3mm

Qor findings-ka saddex leh nidaam:

| Qoraalka | Waxqabad ama Allowable Wear | Alaabta Qiimaynta |

|---|---|---|

| Roller Flange | ≤8mm | Digital Caliper |

| Axle Bore | ≤0.3mm | Bore Gauge |

| Track Link Pin | ≤2.5mm | Wear Gauge Set |

Clean roller cavities with solvent before reassembly and torque axle nuts to OEM specifications (±5% tolerance) using a calibrated torque wrench.

Preparing Tools, Materials, and Correct Replacement Components

Essential Tools and Materials for Track Roller Replacement

Successful replacement requires:

- Hydraulic jacks (10-30 ton capacity)

- Torque wrench (300-600 Nm range)

- Qalabka saabka

- Diri la socda (NLGI #2 ama mid qof leh)

- ISO 898-1 Koonfur 10.9 bolt

Warqada ahaanta ah—ka mid ah botiyo ee gacanta iyo qalabka la xirgali karo ee hidoolik—waxa ay u muhiimsan tahay. Qalabka aan la soo saaray waxa ay ku biirkaan doontaa 34% ka soo horjeedka qurxaha ee la xiriisay midgabayga (2023 Equipment Maintenance Report).

Dalbo Dhaafashada Xulashada ee Buldozerka iyo Excavatorka

Dooro qeybaha dibadda oo la xiriisaa nooca dhagaxda (single/double) iyo qiyasyada ayl (±1 mm). Excavatorka hoose 20 tons, rollerada dhagax ee laba waxa ay siiyaan 23% ka fiican ee dhaafashada ee laabta. Ogaalaya dhammaadka oo la isticmaalo OEM ee diagrams:

- Balacanka rollerka (si gaaban 150-250 mm ee qorshada astaamaha)

- Nooca saafka (labyrinth vs. lip seals)

- Qiyasyada xoogga (55-60 HRC ee isticmaalka caadiga ah)

Ogaalaya Dhammaadka Qeybta oo La Shaqeeyo Iibiyayaasha Daaweyda

Qaabka dhexeeya suurtagalnimada in ay guud ahaan u fuliyaan OEM tijaabiyo ee metallurgy iyo xaqiiqda joometrikada. Iibaaradaha saxda ah ayaa ka qaybqaata ISO 286-2 qiimaha xadka, ka qaadaya dhibka badan ee dhaafada ilaa 40% fiilddii tijaabiyo. Qaabka muhiimka ah ee awood loo baahan yahay, codsadaa warqadaha xaqiijinta material (MTRs) oo faa'iido leh habka isla'ka (tusaale ahaan, 42CrMo4/4140 ferraajin).

Pro Tip: Kala soo hor tag ama dhammaadka qaabka la xiri karaa, lambarka siriilka ah ee aaladda, taariikhda adeegga, iyo kharashka horaynta ee horay.

Qaadooyinka Aman iyo Adeegga Saxda ah ee La Iska Leeyahay

Tijaabiyo ee Aman Muhiimka ah Wakiin Laga Socdaa Qaabka Gudaha

Kuligaa hore waxbarashada, waa in la sameeyo xukumooyinka (LOTO) si aan la kiciin wax kale oo qalabka la sameeyo waqtiga la isticmaalayo. Hadaalka xun ku xiran waa muhim. Kooxda waxbarashada waa in la leeyahay alaabta ogola jiray ANSI sida botaska laba iyo kubadda qadka sare, iyo xilka caawiya ee ogola jiray marka la isticmaalayo qalabka. Marka la dejiyaa excavator, hubi in uu dhamaanayo dhulka leyn. Ii istaagaa jidhka saahe waxaana laga yaabaa in la isticmaalo jaalada dhexe oo xoog leh. Sidii ku cad in luqadaha Shaqaalaha ee 2022 ayaa sheegay, in kasto laba iyo tobnaadka dhammaadka dhexe ee jidhka waa dhacay sababtoo ah qalabka aan la isku dhaafin. Ha aadna soo jeedda in aad buuxiso nidaamka hydraulics ganacsiga ah ee kala duwan oo dhan. Kala birta yar yara waxba ka samayn karaa dhibaatooyin weyn ganacsiga la soo saaray, kadibna mid aan kulan kari doonin waqtiga shaqada.

Teganka iyo Xilka Ganacsiga ee Excavator ee Amaanadda si loogu galeeyo dhibaatooyin

Hadda kaliya hubi kartaa sharcigii loo qaybiyay oo kala soocida manufacturerka ee ogolaaysan ee jacking. Waxaan aragay dhibaatada badan oo ay soo bixisay cylinderska hydrauliska, kaas oo muuqda 17% ee dhammaadka kharashka ee excavatorka sanadkii u dhaxaysay sababtoo ah qaabka aan la midaynayn midabka. Haddii lagu taagayo qalabka, wada shaqey 20-ton jack stands oo la mid ah blockhoyinka iyo steel cribbing oo 4 inch si aad u kala soocda. Hantida ugu horreya! Kahor marxaladda dhammaan la socda 15 feet marka lagu sameeyo shuqul lahayd oo kala duwan iyo ha aadna iska qaadna OSHA guidelineska ee qalabka caasimada badan ee tijaabada midabka oo la xidhiidha iyo in aad hubto oo kala soocodeyda ayaa la ogol yahay. Haddii aad ugu horeeyo Track Rollerka cusub ee Bulldozer Excavator, hubi markaas oo dhammaan ayaa leh midabka oo la socda gravelka la xidhay ama la xidhay concreteka si aad u dhaqan karto dhibaatada aan la taumayn.

Shuqulka Track Rollerka iyo tijaabada ka dib marka la saaray

Ka soo saar Track Roller-ka xun

Bilowga oo balaadha track tensioner-ka si aan la helo farsaad la shaqo. Ka dibna, soo saar chassis-ka midig oo hantiyaha ama jachaarrada hydraulic la fiicanayo, ka dibna dejji midig oo la tiro badan oo in la soo dejjio. Marka la soo saaro bolt-ka la dhigay, isticmaal torque impact iyo hubi sida ay ku dhex jirta iyo meesha ay soo baxay. Waxaa jiren kadhan mid ka mid ah ayaa jiray dhamaan wakhtiga ay ku jirtay. U qaad kharash oo la xidhay oo keliya la socda 10 ilaa 15 daqiiqo ka dibna isku day mar kale. Ha aadna la taaban hubinta shaft-ka gudbiyaha iyada oo karka jirka ama galling-ka. Waa in la xusuusado, waxaa jiren badan oo ka horan ayaa dhacay sababtoo ah wargelka jirka ama galling-ka gudbiyaha. Warshadaha waxaa sheegay in 32% ee dhammaystka la soo saaray ayaa dhacay sababtoo ah la taaban jirka gudbiyaha.

Socodka ugu shubida Cilka Cusub ee Buldozerka iyo Kaarka Dhexe

Isku day kala reerka cusub oo leh shakhsi, oo hubiyo orinkeynta saas loogu talagalay. Kaab bannaan ee kala duwan oo kala duwan, ka dibna wax kaab 450-500 Nm oo isticmaalaya fulayda xisaabta ah—ka qayb gala ee qaybtaas waxaa laga baryaa 18% (Wararka Maalmohud, 2022). Hubi in la socda midho kala duwan ee la socda oo la socda marka hore loo jeeda deqda.

Raad gala Tijaabada ee Abaaraha Siyaasadda Saxda ah ee Ugu Badalida

Raad gala tijaabada ee OEM, waxa uu gaar ah oo leh 30 daqiiqo oo socodka yar oo aan laa xidhan in la socdo in la helo socodka saxda ah ee la socda. Qaabka caasimada waxa ay suganaya in la isticmaalayo laasarka siyaasadda ee ku saabsan, qaabka oo la isticmaalayaa 67% ee dukaarka ee la socda in la dhammaysto jirka qalabka.

Lubrika, Dibadda iyo Isbararka Ugu Dambeynta Badalida

Lubrikaa dhamma waxaa u qorxayaa geesaha qeyliyaha lithium-kuwo komabiyada sare ee oo ugu fududa ilaa geesaha cusub ugu baxay siixda. Ka saar geesaha qalabka in la xunaa dhexdhexaadka—dhexdhexaadka waxay abuuri doontaa 41% ee falshada la xidhiidha geeska. La soo naqdaa carruurta hoose ee la xiriijiyay iyo carruurta idlers, isku beddel karta midha oo leh in ay ka weyn 3mm oo xunida flange.

Faaliyaha iyo Xaqiijinta Kharafka Khorashka

Gali carruurta qorxayaa oo dhan 15-20 daqiiqo, la raadgeliyo tracka la xiriijiyay ama isku daynta dhaafsi. Qiimaya kharashka tracka ee xadka iyo xadka cad, isku day ila kaa sarree 25-30 mm ee iska qumrada iyadoo la taliyaa tijaabada taajirka. Buuxi dhammaan xogta in lagu abuuray asaas ee loo isticmaalo ama dhaqan la xaqiijiyo.

Su'aalaha badanaa la isweydiiyo

Waa maxay waajiba ee asaaska ee carruurta track ee carruurta qorxayaa?

Carruurta tracka waxay ka xunaysaa qalabka iyo si gof iyo si gof ugu dhaqaaqaya carruurta tracka ee la xiriijiyay khorashka, ku shubaya xunida dhammaan jiidka.

Waa maxay farka ee carruurta tracka ee ugu dhasha iyo laba flange ee kala duwan?

Qalabka saaraha gudaha waa la eg (suited) kartaa dhulka flat, halka aadka saaraha labad oo leh saaraha la eg (suited) kartaa dhulka hoose (lateral stability) oo leh saaraha iyo dhulka aan la xidhiidhin, taasoo muuqda in ay noqdaan doonayaan (ideal) doonayaasha iyo kaas oo xawaarinta (mining) ee arrimaha.

Sidee karaa faahfaahin (signs) ee arrinka (failure) ee saaraha hortiisa (track roller) ka heli karto?

Faahfaahinta (signs) wuxuu leeyahay saaraha hortiisa (track) aan la xidhiidhin, dhaafaha (vibrations) aan la xidhiidhin, khatarada ful (metallic noises), iyo u dhaqan karta (reduced) natiijada (maneuverability), gaar ahaan marka la doonto (during turns).

Maxaa yeelay waa muhim in la raacayo (follow) tijaabada (guidelines) ee aasaasaha (manufacturer) marka la beddelayo (replacement) saaraha hortiisa (track roller)?

In la raaco tijaabada wuxuu xaq u leeyahay (ensures) in saaraha loogu daadiyo si sax ah, ugu badalo (extends) muddada (lifespan) ee qalabka, iyo in la iman karo (prevents) arrimaha (failures) oo hore (premature).

Jadwal Tixraaca

-

Fahamka Walaalka Qoraxda ee Buldooserka Wajibka iyo Xaaladaha Arrinta Badan

- Qaabka iyo Wajibka Walaalka Walaalka Qoraxda ee Buldooserka Nidaamka Hoose ee Walaalka

- Tallafalka ee Flange ee kow iyo laba Cagaaqa soo saar ee jiidada ee jiidada ee jiidada Codsiyada

- Sidee Ballaadhka Track-ka iyo Ballaadhka Carrida Igu Differa Dheeraadka iyo Calaamadda

- Nidaamyada caadiga ah ee dhiman iyo natiijadaha mekhaaniska ee ka soo dhaafay ballaadhka track-ka oo la yidhaahdo

- Soo saarida Alamaadaha Tuxaansho iyo Sameynada Inspekshanka Qayarka Hoose

- Preparing Tools, Materials, and Correct Replacement Components

- Qaadooyinka Aman iyo Adeegga Saxda ah ee La Iska Leeyahay

- Shuqulka Track Rollerka iyo tijaabada ka dib marka la saaray

-

Su'aalaha badanaa la isweydiiyo

- Waa maxay waajiba ee asaaska ee carruurta track ee carruurta qorxayaa?

- Waa maxay farka ee carruurta tracka ee ugu dhasha iyo laba flange ee kala duwan?

- Sidee karaa faahfaahin (signs) ee arrinka (failure) ee saaraha hortiisa (track roller) ka heli karto?

- Maxaa yeelay waa muhim in la raacayo (follow) tijaabada (guidelines) ee aasaasaha (manufacturer) marka la beddelayo (replacement) saaraha hortiisa (track roller)?