#704,No.2362,Fangzhong Road,Xiamen,Fujian,China,361009 +86-13860439542 [email protected]

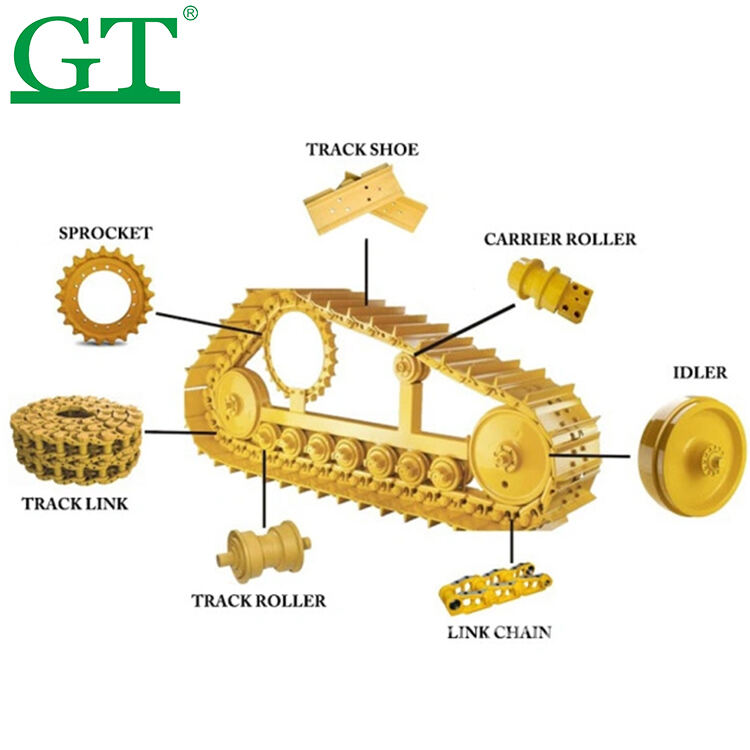

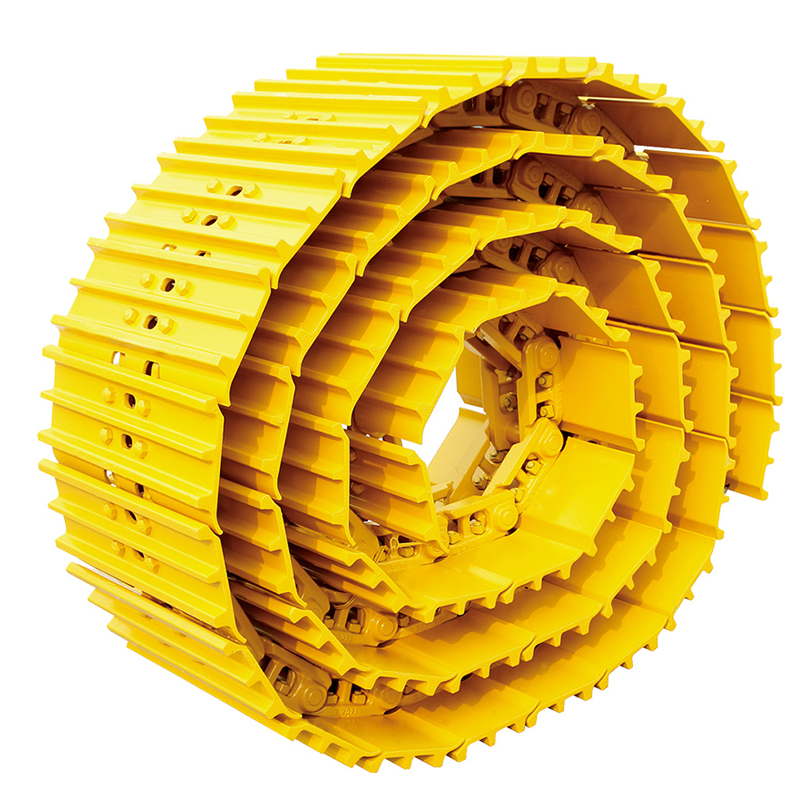

Our bulldozer track chain (bulldozer track chain) covers complete components such as chain links, chain pins, bushings, etc. It is suitable for Caterpillar D5-D9, Komatsu D51-D155, John Deere 650K-850K and other mainstream models. The core components are made of 40CrNiMo high-strength alloy, which is quenched as a whole after forging and molding, and the surface hardness of the chain links reaches HRC58-62, and the abrasion resistance is more than 50% higher than that of ordinary carbon steel models.

Special optimization is made for different operation scenarios: the chain link thickness of mining model is increased by 2mm, which improves the impact resistance by 30%, and is suitable for Carter D7 to operate in hard rock area; the wetland model is equipped with three-layer Viton sealing and waterproof grade IP68, which is suitable for Komatsu D65 to operate for a long time in the muddy land; and the general-purpose model balances the abrasion resistance and cost to meet the needs of daily earth moving projects.

All track chains are reproduced in 1:1 size according to the original drawings, and the error of link spacing is controlled within 0.05mm, which perfectly fits with the drive wheel and guide wheel, and no need to polish and adjust when installing, and the replacement can be completed in 1 hour by an ordinary maintenance team. Measured data show that under the average daily operating intensity of 8 hours, the service life is 40% longer than similar products, and the comprehensive reduction of equipment maintenance costs by 35%.