#704,No.2362,Fangzhong Road,Xiamen,Fujian,China,361009 +86-18350098686 [email protected]

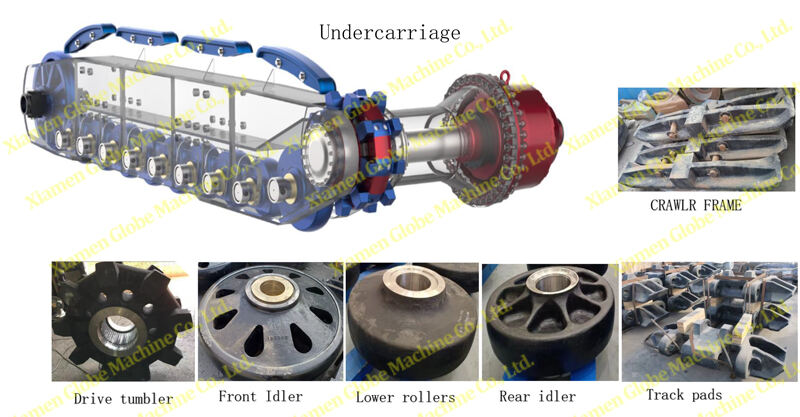

The undercarriage system, often referred to as “Four Wheels and One Belt,” plays a critical role in the overall performance and longevity of a rope shovel. Our complete product line includes all essential components—drive tumbler, front idler, rear idler, lower rollers, and track shoes—designed and engineered to withstand the most demanding working environments.

1. Drive Tumbler (Sprocket)

The drive tumbler is the heart of the undercarriage system. It engages directly with the track links to transmit torque from the powertrain to the tracks, propelling the machine forward or backward. Our drive tumblers are forged from high-strength alloy steel and treated with advanced heat processes such as induction hardening to deliver maximum wear resistance and impact toughness. The precision-machined tooth profile ensures smooth engagement, reducing link wear and extending service life.

Key Features:

Precision-forged steel construction with hardened tooth surfaces

Optimal tooth geometry for smooth power transfer

Available in single- or split-segment design for easier servicing

2. Front Idler (Tensioning Wheel)

Located at the front of the undercarriage, the front idler serves two critical functions: guiding the track and maintaining proper tension. Our idlers are cast from solid steel and finished with high-precision machining to ensure concentricity and surface integrity. Each idler integrates an internal automatic tensioning system that provides consistent tension, reducing the risk of derailment and improving track alignment.

Key Features:

High-durability materials with superior wear resistance

Sealed bearing assemblies for long-term operation in harsh conditions

Automatic tensioning mechanism for simplified maintenance

3. Rear Idler (Optional in Some Models)

The rear idler enhances track alignment and stability, particularly in larger or heavy-duty rope shovel models. Engineered for lateral load capacity, it plays an important role in maintaining straight-line tracking under severe operational stresses. Our rear idlers feature a dual-guide structure and are built to absorb both axial and radial forces during machine maneuvering.

Key Features:

Reinforced rib design for increased structural rigidity

Dual-seal bearing system to resist contamination

Ground guide surface to ensure straight-line travel

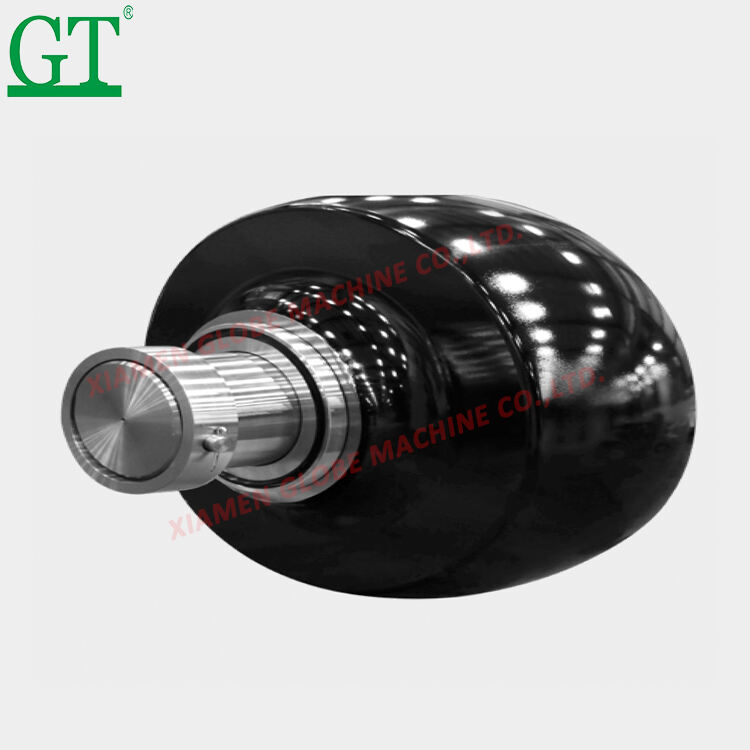

4. Lower Roller (Track Roller)

Track rollers support the entire weight of the shovel and maintain consistent contact between the track and the ground. Our rollers are manufactured with an integrated forged body and shaft design, delivering superior strength and durability. Multi-layer sealing protects internal components from dust, mud, and water ingress, making them ideal for high-impact, abrasive environments such as mining and tunneling.

Key Features:

Load-rated for extreme working conditions

Self-lubricating design reduces downtime and maintenance

Highly reliable seal system extends operational life

5. Track Pad (Crawler Shoe)

Track pads are the only undercarriage component in direct contact with the ground and are essential for providing traction, load distribution, and stability. We offer a wide range of pad designs—including single, double, triple grouser, and slip-resistant types—to suit various terrains and operational requirements. Made from high-manganese or alloy steel, each shoe undergoes heat treatment and surface strengthening to resist fatigue and cracking under cyclic loading.

Key Features:

Customizable pad designs for different soil and terrain conditions

High-toughness materials for excellent shock resistance

Anti-slip features for improved gradient and soft ground performance

Why Choose Our Complete Undercarriage Package?

Seamless Compatibility: Fully compatible with major rope shovel models; easy to install and replace

Extended Service Life: All components are engineered for durability under high-stress applications

Low Total Cost of Ownership: Reduced wear and lower maintenance demands translate to long-term savings

Adaptability: Options available for special environments, including cold climates, corrosive conditions, and heavy-duty operations

6.Crawler Frame – Structural Backbone of the Undercarriage System

The crawler frame serves as the primary structural foundation of the entire undercarriage assembly. It connects and supports all key components—such as the drive tumbler, idlers, rollers, and track shoes—while bearing the full operational weight and dynamic loads of the rope shovel. Designed for extreme-duty applications, our crawler frames are fabricated from high-strength, low-alloy steel using precision welding and stress-relief treatments to ensure exceptional structural integrity.

Every frame is engineered with optimized load paths and reinforcement zones, making it highly resistant to torsional stress, bending forces, and fatigue over prolonged cycles. Key contact surfaces are machined to tight tolerances to guarantee proper fitment with undercarriage elements, ensuring smooth track motion and even load distribution across components.

Key Features:

High-Strength Construction: Welded from wear-resistant, structural-grade steel for maximum durability in mining and heavy excavation environments

Precision Engineering: Machined interfaces and alignment guides ensure accurate assembly and minimize component wear

Stress-Relieved Structure: Heat-treated to eliminate residual welding stress and improve resistance to cracking under heavy loads

Customizable Design: Available in standard and OEM-specific configurations; optional mounting points for sensors, guards, or service access panels

Model parts We can supply

| Electric Shovel | |||

| TZCO | Hitachi | Liebherr | Caterpillar |

| WK-12 | EX2500/EX2600 | R9200 | CAT7395 |

| WK-20 | EX3600 | R9400 | CAT6030 |

| WK-35 | EX5500/EX5600 | R9600 | CAT7495HD/HR |

| WK-55 | EX8000 | R9800 | CAT6040 |