#704,No.2362,Fangzhong Road,Xiamen,Fujian,China,361009 +86-18350098686 [email protected]

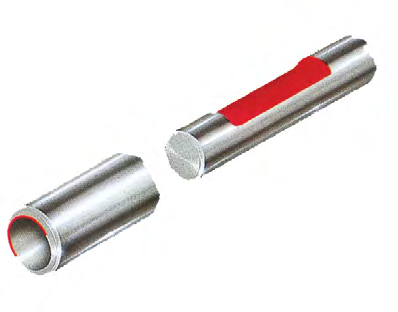

1. Measuring Internal Wear (Chain Stretch) Internal wear on sealed and greased chains is primarily identified by chain stretch (pitch extension).

Inspection Method: Measure the distance between pin centers over a span of 4 to 5 links.

Assessment: Compare the measured data against the OEM specifications for a new chain to determine the percentage of wear.

2. Troubleshooting: Worn Pin Ends External wear on pin ends is often caused by hillside operation, uneven terrain, incorrect chain tension, or excessive roller wear.

Corrective Action: If chain elongation is within limits, adjust the chain tension and rotate the rollers to distribute wear.

Installation Note: If this wear pattern appears immediately after installing a new undercarriage, inspect the track guards. Ensure they are not positioned too close to the chain, causing friction.

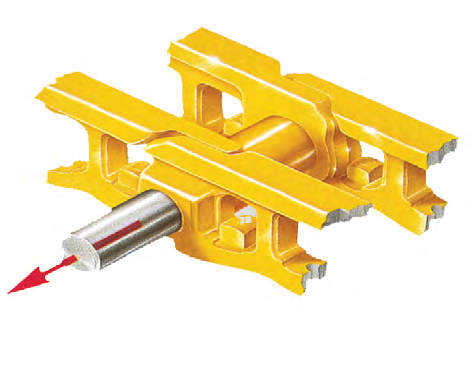

3. Troubleshooting: Loose Pins If there are no assembly errors, loose pins are typically caused by excessive bending stresses (lateral loads) during heavy-duty operation.

Prevention & Solution:

Inspect and replace worn track shoes immediately.

Check and re-torque track bolts.

Recommendation: Consider fitting narrower shoes to reduce leverage and bending stress on the pins.