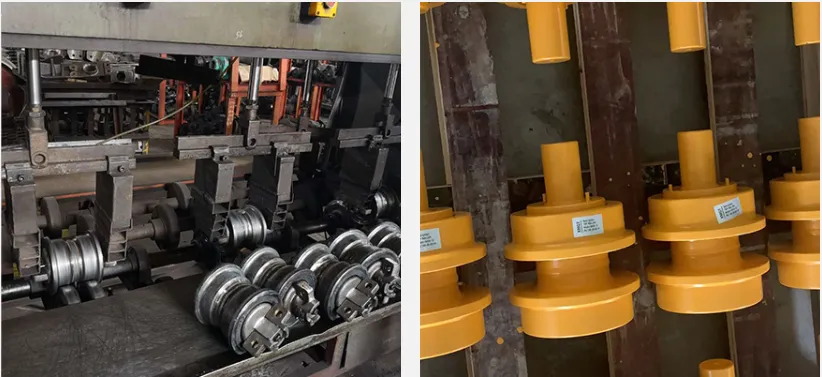

Anatomy of Excavator Carrier Rollers and Idlers

Excavator carrier rollers and idlers form the foundation of efficient undercarriage systems, enabling controlled movement across rugged terrains. These components manage vertical loads and horizontal forces while maintaining structural integrity, directly impacting equipment stability, fuel efficiency, and operating costs.

Core Functions in Undercarriage Systems

Carrier rollers maintain upper track alignment and prevent sagging, ensuring proper sprocket engagement. Hydraulic idlers serve as track guides and tension regulators, compensating for chain elongation. Bottom rollers distribute weight loads using hardened bearings to minimize friction during operation.

Interaction Between Rollers, Idlers, and Track Chains

These components create a continuous rolling surface that adapts to ground contours. Track chains transfer power through idler-mounted tensioners while rollers prevent lateral slippage during turns. Proper alignment ensures even contact pressure, preventing premature wear on link bushings.

Proactive Maintenance Techniques for Carrier Rollers

Debris Removal Protocols to Prevent Component Binding

Remove accumulated material from roller frames and idler cavities using compressed air or pressurized water—especially after operating in clay or abrasive soils. Compacted debris creates stress points that accelerate flange wear and track misalignment.

Lubrication Strategies for Pivot Points

Use high-temperature grease specified by manufacturers, applying every 50 operating hours in standard conditions. Avoid overgreasing, which attracts abrasive particles and compromises seal effectiveness.

Surface Corrosion Prevention Methods

Apply zinc-rich primer coatings to exposed metal surfaces and inspect weld points and bearing housings quarterly. For equipment stored in humid environments, use breathable covers to prevent condensation buildup.

Common Causes of Idler and Roller Premature Wear

Impact of Operational Missteps: Spinning and Overspeeding

Excessive track spinning generates friction heat, degrading bearings and treads. Track slippage exceeding 20 seconds per cycle reduces component lifespan by 30%. Pivot turns and overspeeding on inclines further stress components, leading to flange fractures.

Environmental Factors: Mud, Rocks, and Extreme Temperatures

Abrasive materials like silica-rich mud erode roller shafts, while granite fragments cause impact forces up to 12,000 PSI on idlers. Extreme temperature swings (-40°F to 120°F) weaken metal cohesion, reducing component durability by 18% annually.

Mechanical Stress from Improper Track Tension

Deviating ±10% from OEM track tension specs increases bearing wear by 40%. Sagging tracks create uneven loading, while over-tightened chains accelerate seal failure. Misalignment exceeding 3° concentrates wear on a small surface area.

Diagnosing Wear Patterns in Undercarriage Components

Visible Indicators: Flanges, Seals, and Bearing Surfaces

Flange wear exceeding 30% thickness reduction compromises track stability, while cracked seals expose bearings to contaminants. Look for:

- Asymmetric roller flange erosion

- Degraded seals at roller/journal interfaces

- Pitting or embedded debris in bearing races

Operational Symptoms: Uneven Tracking and Abnormal Noises

Subtle performance shifts warn of future failures. A 5° tracking misalignment increases link wear by 180%. Listen for:

Persistent drift during travel signals uneven idler wear or chain elongation.

Optimizing Track Tension and Alignment

Measurement Techniques for Proper Tensioning

Ensure precision using these methods:

- Track plate measurement: Maintain a 15-30mm gap between track chain and straight rod (varies by environment).

- Raised track method: Verify 320-340mm clearance between track plates and frame.

Corrective Actions for Sag and Misalignment

- Address sag by greasing adjuster valves in 1/4-pump increments.

- For lateral misalignment >10mm, realign idlers using laser-guided systems.

- Replace worn adjuster seals showing leaks or cracks.

Replacement Thresholds for Critical Components

When to Retire Worn Idlers

Replace idlers when:

- Internal bearings become exposed (raises derailment risk by 63%).

- Structural cracks exceed 3mm (indicates fatigue damage).Most manufacturers recommend replacement after 6,000–8,000 service hours.

Carrier Roller End-of-Life Indicators

Failed rollers show:

- ≥80% seal degradation (allowing lubricant contamination).

- ≥3° misalignment (causing asymmetric wear).

- ≥5mm pivot joint play (often with grinding noises).Monthly flange thickness checks help detect wear early.

Field Case Study: Extended Lifespan Through Scheduled Maintenance

A mining contractor achieved a 25% cost reduction in undercarriage repairs by implementing strict maintenance:

- 500-hour inspection intervals for rollers and idlers.

- Immediate seal replacement for those with ≥2mm wear. This extended component life by

- .

FAQ

What are carrier rollers and idlers used for in excavators?

Carrier rollers and idlers are components of the undercarriage system that help maintain track alignment, distribute weight, prevent sagging, and regulate track tension in excavators.

How can I prevent premature wear on idlers and rollers?

Regular maintenance, proper lubrication, monitoring environmental impact, and ensuring accurate track tension and alignment contribute to preventing premature wear on idlers and rollers.

What signs indicate it's time to replace excavator idlers?

Signs for idler replacement include exposed internal bearings and structural cracks exceeding 3mm. Most manufacturers suggest replacement after 6,000–8,000 service hours.

How do I maintain proper track tension in excavators?

Use measurement techniques such as track plate measurement and raised track method to ensure proper tension and take corrective action for sag and misalignment with tools like laser-guided systems.

Table of Contents

- Anatomy of Excavator Carrier Rollers and Idlers

- Proactive Maintenance Techniques for Carrier Rollers

- Common Causes of Idler and Roller Premature Wear

- Diagnosing Wear Patterns in Undercarriage Components

- Optimizing Track Tension and Alignment

- Replacement Thresholds for Critical Components

- Field Case Study: Extended Lifespan Through Scheduled Maintenance

- FAQ