#704,No.2362,Fangzhong Road,Xiamen,Fujian,China,361009 +86-18350098686 [email protected]

The Hidden Cost of Undercarriage Failure in Excavator Operations Quantifying downtime, labor, and replacement expenses across high-usage fleets Excavator undercarriage failures trigger costly operational disruptions. Industry studies show that negl...

VIEW MORE

Understanding the Global Supply Chain for Bauer Rig Parts Key Sourcing Regions and Tiered Supplier Structure Parts for Bauer rigs come from special manufacturing centers throughout North America, Europe, and East Asia, creating what amounts to a co...

VIEW MORE

Understanding Rubber Track System Components and Core Functionality The role of rubber tracks in load distribution, mobility, and machine stability Rubber tracks form the main connection point between machines and whatever surface they're working o...

VIEW MORE

The Engineering Behind Triangular Rubber Tracks How Triangular Geometry Enhances Structural Integrity and Load Distribution Rubber tracks shaped in triangles actually work better for distributing weight and keeping things structurally sound compare...

VIEW MORE

Superior Traction and Stability on Challenging Terrains How Triangular Rubber Tracks Enhance Grip on Uneven Surfaces Rubber tracks shaped like triangles give machines better grip because they touch the ground over a bigger area thanks to their spec...

VIEW MORE

Minimizing Downtime with Reliable Hydraulic Track Press Systems Challenges of Frequent Downtime in Traditional Press Systems Old school press systems tend to break down without warning, eating away at factory time with about 800 lost hours each yea...

VIEW MORE

Operator Errors and Safety Violations with Hydraulic Track Press Common operator training gaps leading to human error A lot of accidents involving hydraulic track presses actually come down to basic training problems instead of faulty equipment. Re...

VIEW MORE

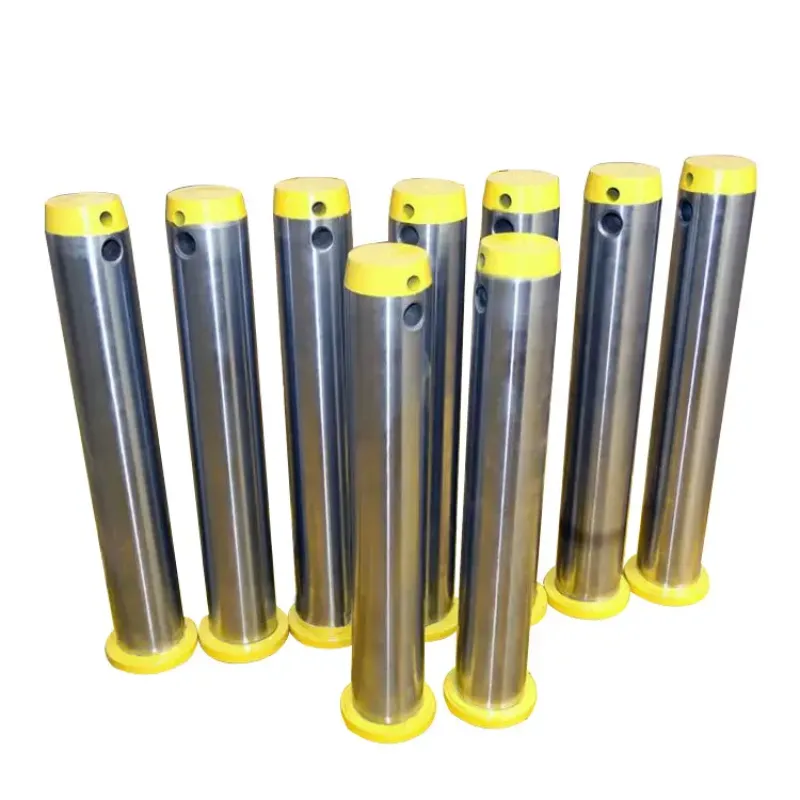

Material Selection and Composition for Excavator Bucket Pins Key Properties of Wear-Resistant Materials in Excavator Bucket Pin Applications Wear-resistant excavator bucket pins must meet three essential mechanical criteria: Hardness (55–60 ...

VIEW MORE

The Technological Evolution of Bauer Drilling Rigs: From Mechanical Systems to Smart, AI-Driven Machines Historical Advancements in Drilling Equipment Shaping Modern Foundation Technology Back in the 1930s, foundation drilling was all about those o...

VIEW MORE

The Role of Rubber Tracks in Enhancing Operational Efficiency How Rubber Tracks Improve Mobility and Reduce Downtime in Construction Machinery Construction machines can actually move around rough ground and narrow spots much better when they have r...

VIEW MORE

The Science Behind Hardening Treatments for Enhanced Track Roller Performance Why Wear Resistance Is Critical in Heavy-Duty Track Rollers In abrasive environments like mining and construction, track rollers face sustained contact pressures exceedin...

VIEW MORE

The Critical Role of High-Strength Bucket Pins in Excavator Durability and Performance Why Modern Excavation Demands Higher Stress Resistance in Bucket Pins These days, excavation work deals with all sorts of tough stuff like reinforced concrete an...

VIEW MORE