Material Selection and Composition for Excavator Bucket Pins

Key Properties of Wear-Resistant Materials in Excavator Bucket Pin Applications

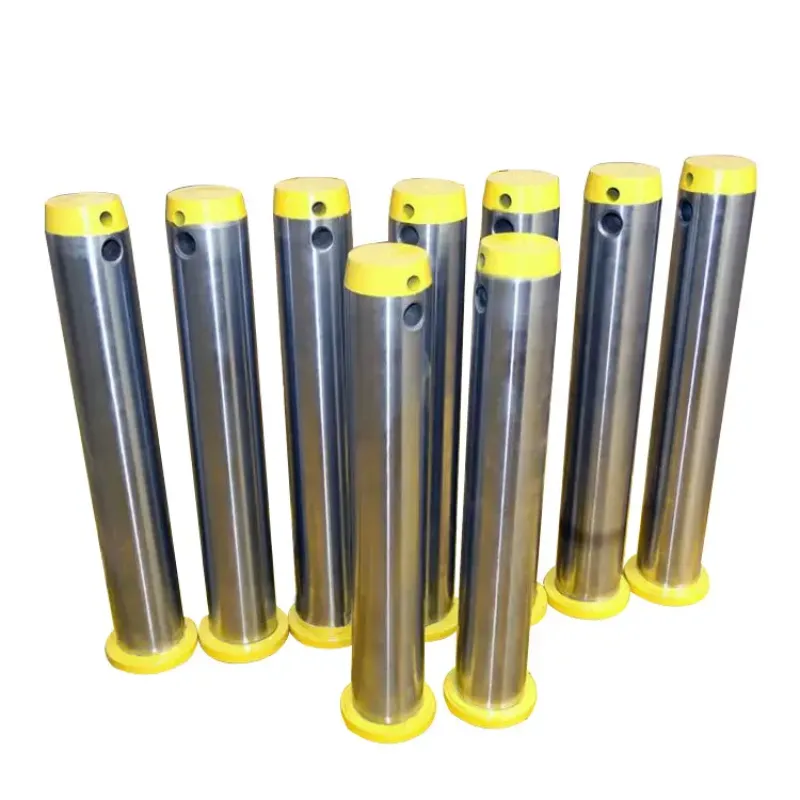

Wear-resistant excavator bucket pins must meet three essential mechanical criteria:

- Hardness (55–60 HRC) to resist abrasive wear

- Impact resistance (>40 J at -20°C) for shock absorption during high-load digging

- Yield strength exceeding 1,200 MPa to prevent plastic deformation

Pins meeting these standards reduce replacement frequency by 62% compared to standard-grade components (ASTM International 2023).

Comparative Analysis of Steel Alloys Used in Excavator Bucket Pin Manufacturing

A 12-month field study revealed significant performance differences among alloy types:

- Boron-alloyed steels exhibited 23% less diameter reduction than conventional grades

- Micro-alloyed steels with vanadium or niobium demonstrated 18% higher load capacity

- Case-hardened alloys delivered 31% longer service life in high-impact environments

Material selection should align with operational demands—high-silicon steels, for instance, offer superior corrosion resistance in wet or chemically aggressive conditions.

Advanced Heat Treatment: Achieving Optimal Hardness and Toughness

Through-Hardening vs. Surface Hardening: Balancing Strength and Brittleness

While through-hardening provides consistent material properties, surface treatments like case hardening serve specialized roles:

- Through-Hardened Pins: Best suited for applications requiring uniform wear resistance without stress risers

- Case-Hardened Components: Ideal for bushings needing hardened surfaces (60–65 HRC) over tough, ductile cores

Field data indicates through-hardened pins last 2.3× longer than surface-hardened equivalents under continuous excavation loads. However, precise tempering at 200–300°C is critical to avoid brittle fracture.

Case Study: Enhanced Fatigue Life Through Precision Heat Treatment

A North American manufacturer reduced pin replacements by 72% after adopting a refined heat treatment cycle:

- Austenitizing at 845°C for 90 minutes

- Quenching in fast oil at 60°C

- Tempering at 285°C for 2 hours

This protocol increased fatigue resistance by 58% (per ASTM E466 testing) while maintaining impact toughness between 25–30 J at -20°C. Post-implementation records showed service intervals extending to 14 months under 25-ton digging loads, surpassing the industry average of 8 months.

Surface Treatments to Enhance Durability and Reduce Friction

High-frequency quenching for improved surface hardness in pins and bushings

High-frequency induction quenching selectively hardens the surface of pins and bushings to 55–60 HRC by rapidly heating and cooling the outer layer. This creates a wear-resistant martensitic shell while retaining a ductile core, minimizing distortion and ensuring dimensional stability—critical for precision-fit components operating in abrasive soils.

Nitriding and chrome plating: Reducing wear and friction in high-load conditions

When we talk about nitriding, what happens is nitrogen gets absorbed into metal surfaces which makes them harder and better at resisting fatigue over time. Some studies have shown parts treated this way can last around 30% longer before failing. Then there's chrome plating, which cuts down friction between moving parts by about 40% when compared to regular metal surfaces under load conditions. Tribologists at Coll McEachern Associates noted this back in 2024 during their research work. Both these surface treatments really shine when equipment operates in places where dust and grit tend to stick to components, helping prevent that annoying type of wear where materials actually bond together during operation.

Performance evaluation of surface-treated components under continuous operation

After 2,000 service hours, surface-treated pins show 35% lower wear rates than untreated counterparts. Operators report a 50% reduction in unplanned downtime when using treated pin-bushing pairs, attributed to stable friction behavior even under peak hydraulic pressures exceeding 35 MPa.

Mechanisms of Wear in Excavator Bucket Bushings and Influencing Factors

The bushings on excavator buckets tend to wear down in three main ways: first, when small particles create abrasive wear, second, when metal touches metal causing adhesive wear, and third, from surface fatigue because they get loaded repeatedly. How these bushings break down depends a lot on how they're used. If there's even just a little bit of misalignment, say over half a degree, it can make the wear happen three times faster. And if lubrication isn't good enough, the temperature at the contact point jumps up to around 150 to 200 degrees Celsius, which makes the materials soften and wear out quicker. Field tests done recently showed that in areas with lots of sand, the bushings actually lose between 0.8 and 1.2 millimeters every thousand operating hours because the quartz in the sand acts like tiny cutting tools wearing away at the surfaces.

Assessing Replacement Timing Based on Wear Patterns and Operational Load

Replacement thresholds vary by machine size and loading:

- 20–30-ton excavators: Replace bushings at 1.5–2.0 mm wear depth

- 50+ ton excavators: Replace at 1.0–1.2 mm wear depth under radial loads >35 MPa

Research shows wear rates triple when operational loads exceed 40% of the material’s yield strength, underscoring the importance of real-time monitoring for predictive maintenance scheduling.

Resolving the Hardness vs. Brittleness Paradox in Bushing Material Design

Advanced alloys such as 34CrNiMo6 achieve 58–60 HRC via vacuum heat treatment while maintaining 12–15% elongation through nickel and molybdenum additions. This combination reduces stress concentration fractures by 60% compared to traditional high-carbon steels, as validated in a 2,500-hour mining trial.

Precision Matching of Excavator Bucket Pins and Bushings

Importance of Dimensional Accuracy and Alignment in Pin-Bushing Fit

Dimensional tolerances within ±0.05 mm ensure optimal contact and load distribution between pins and bushings. Proper alignment reduces stress concentrations by 62% (Journal of Heavy Equipment Engineering, 2023), preventing premature bore ovalization. Critical dimensions include:

- Pin diameter (typically 80–120 mm for 20–50 tonne machines)

- Bushing wall thickness (minimum 15% of pin diameter)

- Parallelism tolerance (<0.1 mm/m across mating surfaces)

Angular misalignment exceeding 1.5° leads to asymmetric loading, accelerating wear by 2–3× during routine operations.

Frequently Asked Questions

What materials are typically used in the manufacturing of excavator bucket pins?

Excavator bucket pins are commonly made from high-carbon steels which provide an optimal balance of hardness and toughness. Other materials like boron-alloyed and micro-alloyed steels are also used for specific performance benefits.

How does heat treatment enhance the performance of bucket pins?

Heat treatment, such as through-hardening, improves the uniform distribution of hardness across the pin which enhances wear resistance, ductility, and strength, thus extending the service life of the pins under demanding conditions.

Why is alignment important in the pin-bushing fit?

Proper alignment ensures optimal load distribution and reduces stress concentrations, which can prevent premature wear and elongate the service life of the components.

What are the common wear mechanisms in excavator bucket bushings?

The three main wear mechanisms include abrasive wear from small particles, adhesive wear from metal contact, and surface fatigue due to repeated loading.

How can surface treatments like nitriding and chrome plating benefit excavator components?

Surface treatments such as nitriding and chrome plating enhance the hardness and reduce the friction of component surfaces, which helps in extending their wear life especially in harsh environmental conditions.

Table of Contents

- Material Selection and Composition for Excavator Bucket Pins

- Advanced Heat Treatment: Achieving Optimal Hardness and Toughness

- Surface Treatments to Enhance Durability and Reduce Friction

- Mechanisms of Wear in Excavator Bucket Bushings and Influencing Factors

- Assessing Replacement Timing Based on Wear Patterns and Operational Load

- Resolving the Hardness vs. Brittleness Paradox in Bushing Material Design

- Precision Matching of Excavator Bucket Pins and Bushings

-

Frequently Asked Questions

- What materials are typically used in the manufacturing of excavator bucket pins?

- How does heat treatment enhance the performance of bucket pins?

- Why is alignment important in the pin-bushing fit?

- What are the common wear mechanisms in excavator bucket bushings?

- How can surface treatments like nitriding and chrome plating benefit excavator components?