Key Materials for Track Roller for Bulldozer Excavator Applications

Overview of Common Alloy Steels: 40CrMo, 42CrMo, 40Mn2, and 50Mn

The track rollers used on bulldozers and excavators depend heavily on specific alloy steels including 40CrMo, 42CrMo, 40Mn2, and 50Mn because these materials strike just the right balance between strength and resistance to wear. Most of these steels have carbon content ranging from about 0.35% up to around 0.55%, plus important alloying ingredients like chromium, molybdenum, and manganese mixed into them. Take 42CrMo for example it typically contains between 0.38% and 0.45% carbon alongside roughly 0.90% to 1.20% chromium, which makes it really good at hardening throughout the material. Meanwhile, 50Mn stands out with its increased manganese level (also around 0.90% to 1.20%), giving it superior surface hardness when dealing with those tough abrasive conditions equipment often faces in real world operations.

Comparative Analysis of Mechanical Properties in Track Roller Steels

- 40CrMo: Tensile strength of 980–1,180 MPa, suitable for medium-load applications

- 42CrMo: Offers superior toughness (1,080–1,220 MPa tensile strength) and fatigue resistance

- 50Mn: Achieves high surface hardness (HRC 55–60) but has lower impact toughness than chromium-alloyed steels

Industry studies show a 23% increase in service life when switching from 40Mn2 to 42CrMo in high-impact environments.

Why 42CrMo Is Preferred for High-Stress Excavator and Bulldozer Track Rollers

When it comes to materials for high stress applications, 42CrMo stands out because of how stable it stays when subjected to repeated loads over time. Tests on parts from heavy machinery show that this alloy's tempered martensite structure actually stops cracks from spreading about 34 percent better than 50Mn does. That makes a real difference in long term durability. What's interesting too is how chromium works together with molybdenum to boost resistance against rust and corrosion. This combination proves particularly useful where there's moisture or saltwater exposure, like those tough conditions found at coastal mines where equipment constantly battles harsh elements.

Role of Carbon and Alloy Content in Wear Resistance of Track Rollers

Carbon content (typically 0.40–0.50%) directly influences hardness, while alloying elements enhance secondary performance traits:

- Chromium (0.9–1.2% in 42CrMo): Increases hardenability and oxidation resistance

- Molybdenum (0.15–0.25%): Refines grain structure, improving fracture toughness

This combination yields a wear coefficient of 0.0018 mm³/Nm in ASTM G65 testing, outperforming unalloyed steels by 40%.

Microstructure Optimization of Steel for Enhanced Durability and Longevity

Controlled heat treatment produces bainitic or tempered martensitic microstructures. In track rollers, a lath martensite structure with 10–15% retained austenite ensures optimal stress distribution. Advances in thermo-mechanical processing have extended component lifecycles by 19% in field trials, particularly under the combined torsional and axial loads common in excavator undercarriages.

Quenching and Tempering: Core Techniques in Track Roller Heat Treatment

Quenching rapidly cools alloy steels such as 42CrMo and 50Mn to form a martensitic structure, achieving surface hardness up to 58–62 HRC. Subsequent tempering at 400°C–600°C reduces brittleness by redistributing carbon atoms, preserving core toughness essential for bulldozer track rollers operating on uneven terrain.

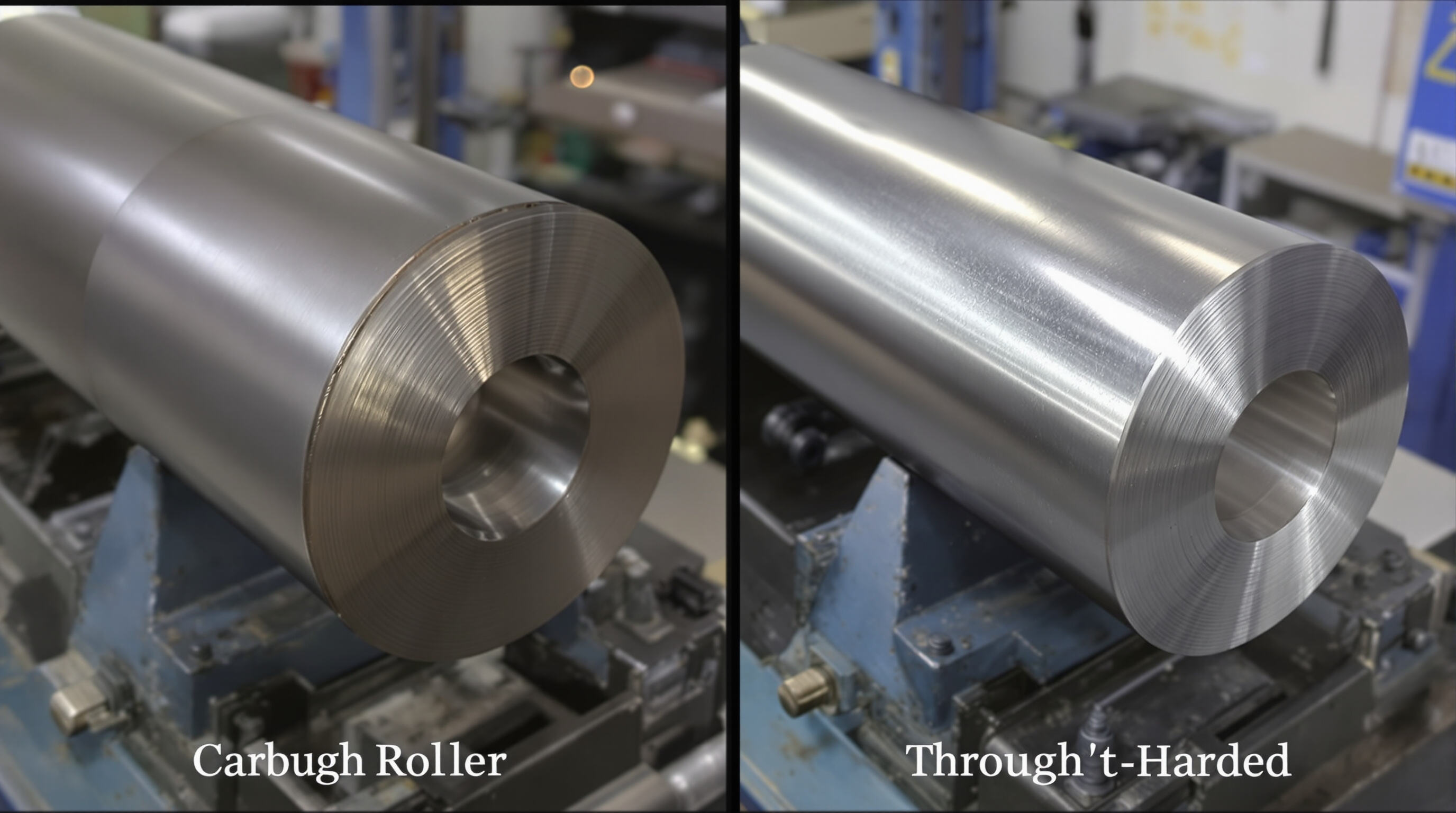

Carburizing vs. Through Hardening: Choosing the Right Method for Wear Resistance

When it comes to excavator track rollers that need to handle constant pressure, through hardening gives them a pretty even hardness range between 50 and 55 HRC, which works really well for these applications. Carburizing takes things a step further by creating a harder outer layer that can reach up to 60 HRC while keeping the inside material tougher and more flexible. Field testing shows these carburized parts last about 18 percent longer when working in sandy conditions where abrasion is a big concern. The trade off though? These same carburized rollers tend to crack more easily when subjected to sudden heavy impacts compared with their through hardened counterparts, something many maintenance teams have noticed after years of equipment operation.

How Tempering Reduces Brittleness While Maintaining Surface Hardness

Post-quench tempering converts brittle martensite into tougher tempered martensite, retaining about 90% of initial hardness while significantly improving fracture resistance. For track rollers used in sub-zero conditions (below -20°C), two-stage tempering at 200°C and 550°C boosts Charpy impact toughness by 30% without compromising wear performance.

Impact of Heat Treatment on Mechanical Properties of 40CrMo and 50Mn

When we apply controlled oil quenching at around 850 degrees Celsius, the yield strength of 40CrMo reaches at least 980 MPa, which makes this material ideal for those really tough jobs in heavy duty excavators. On the other hand, water quenching works well with 50Mn steel to get a much higher hardness rating between 55 and 58 on the Rockwell scale. However there's a catch here. The process demands very careful tempering otherwise these components might suffer from stress corrosion problems especially when deployed near coastlines where saltwater exposure is common. Looking at fatigue life tests reveals something interesting too. After operating under load for 15,000 hours straight, 42CrMo rollers still maintain about 95 percent of their original capacity. That's actually 22 percent improvement compared to similar parts made from 50Mn steel.

Controversy Analysis: Over-Tempering Risks in High-Load Track Roller Applications

Tempering above 650°C can soften 42CrMo surfaces by 12–15 HRC, accelerating wear in demanding mining operations. However, recent research suggests that extended low-temperature tempering (230°C for 8 hours) effectively reduces residual stresses without sacrificing hardness—a crucial advantage for oversized track rollers in 80-ton excavators.

Wear Resistance, Toughness, and Longevity of Track Rollers in Harsh Conditions

Field Performance of 42CrMo Track Rollers Under Abrasive and Impact Loading

42CrMo track rollers excel in high-stress environments due to their balanced microstructure and alloy content. They withstand abrasive particles and impact loads exceeding 750 MPa without spalling. Field data shows these rollers retain 92% of their original diameter after 2,000 hours in quarries—15% better than standard 40Mn2 variants.

Correlation Between Surface Hardness and Wear Resistance in Excavator Track Rollers

Surface hardness (58–62 HRC) strongly correlates with wear resistance. However, exceeding 64 HRC increases brittleness risk by 30%, per metallurgical analyses. Advanced heat treatment achieves optimal hardness gradients, ensuring subsurface toughness (±40 J Charpy impact values) while maintaining wear-resistant surfaces in rock-heavy conditions.

Balancing Toughness and Fracture Resistance in High-Impact Applications

Modern track roller designs overcome the toughness-hardness trade-off through:

- Micro-alloying with chromium (1.2–1.5%) and molybdenum (0.2–0.3%)

- Controlled quenching rates (50–80°C/s)

- Residual compressive stresses (-800 to -1,200 MPa) induced by shot peening

This integrated approach reduces stress concentration by 40% compared to conventional through-hardened parts.

Longevity Data: Track Roller Life Cycles with Optimized Heat Treatment

Properly heat-treated 42CrMo track rollers last 8,000–10,000 service hours in bulldozer applications—60% longer than untreated components. Post-treatment precision machining maintains ±0.05 mm dimensional accuracy, preventing accelerated wear in track chain systems. Recent data indicates optimized rollers reduce replacement frequency by 35% during typical excavator overhaul cycles.

Post-Processing and Real-World Performance of High-Durability Track Rollers

Shot Peening and Surface Rolling: Enhancing Fatigue Life

Shot peening introduces compressive surface stresses that delay crack initiation by up to 300% in bulldozer track rollers. Surface rolling further boosts hardness by 15–20% in 42CrMo components. Together, these processes reduce abrasive wear rates by 34% in quarry operations, as verified by ASTM G65-2022 testing.

Precision Machining After Heat Treatment to Maintain Dimensional Stability

CNC machining after tempering ensures ±0.01 mm tolerances, which are critical for reliable track roller performance. Improper processing sequence can cause 0.3 mm warping in 50Mn components during quenching—sufficient to increase chain wear by 60%. Leading manufacturers now use in-process laser measurement systems to maintain geometrical integrity.

Case Study: Material and Process Optimization in Heavy Machinery

When combining traditional carburizing and shot peening techniques with modern AI controlled tempering processes for 42CrMo excavator track rollers, manufacturers saw impressive results. Testing done throughout 2023 showed these treated components lasted about 40% longer when subjected to regular 12 ton loads during operation. Laboratory analysis through Charpy impact testing revealed better resistance to cracking, achieving around 58 joules of energy absorption even at freezing temperatures of minus 20 degrees Celsius. The cost savings were equally remarkable for mining companies implementing this approach, cutting down yearly replacement expenses by approximately seven hundred forty dollars per individual roller unit across their fleet.

FAQ

What are the primary materials used for track rollers in bulldozers and excavators?

The primary materials used for track rollers in bulldozers and excavators are alloy steels such as 40CrMo, 42CrMo, 40Mn2, and 50Mn. These materials are chosen for their strength and wear resistance.

Why is 42CrMo alloy steel preferred for high-stress applications?

42CrMo is preferred for high-stress applications because of its stable performance under repeated loads, superior crack resistance, and enhanced resistance to rust and corrosion thanks to its chromium and molybdenum content.

What is the advantage of using carburized over through hardened track rollers?

Carburized track rollers have a harder outer layer that improves wear resistance, making them last longer in abrasive conditions. However, they tend to crack more easily under sudden heavy impacts compared to through hardened rollers.

How does heat treatment impact the mechanical properties of track rollers?

Heat treatment, such as quenching and tempering, impacts track rollers by enhancing surface hardness, reducing brittleness, and improving fracture resistance and overall toughness.

Table of Contents

-

Key Materials for Track Roller for Bulldozer Excavator Applications

- Overview of Common Alloy Steels: 40CrMo, 42CrMo, 40Mn2, and 50Mn

- Comparative Analysis of Mechanical Properties in Track Roller Steels

- Why 42CrMo Is Preferred for High-Stress Excavator and Bulldozer Track Rollers

- Role of Carbon and Alloy Content in Wear Resistance of Track Rollers

- Microstructure Optimization of Steel for Enhanced Durability and Longevity

- Quenching and Tempering: Core Techniques in Track Roller Heat Treatment

- Carburizing vs. Through Hardening: Choosing the Right Method for Wear Resistance

- How Tempering Reduces Brittleness While Maintaining Surface Hardness

- Impact of Heat Treatment on Mechanical Properties of 40CrMo and 50Mn

- Controversy Analysis: Over-Tempering Risks in High-Load Track Roller Applications

-

Wear Resistance, Toughness, and Longevity of Track Rollers in Harsh Conditions

- Field Performance of 42CrMo Track Rollers Under Abrasive and Impact Loading

- Correlation Between Surface Hardness and Wear Resistance in Excavator Track Rollers

- Balancing Toughness and Fracture Resistance in High-Impact Applications

- Longevity Data: Track Roller Life Cycles with Optimized Heat Treatment

- Post-Processing and Real-World Performance of High-Durability Track Rollers

-

FAQ

- What are the primary materials used for track rollers in bulldozers and excavators?

- Why is 42CrMo alloy steel preferred for high-stress applications?

- What is the advantage of using carburized over through hardened track rollers?

- How does heat treatment impact the mechanical properties of track rollers?