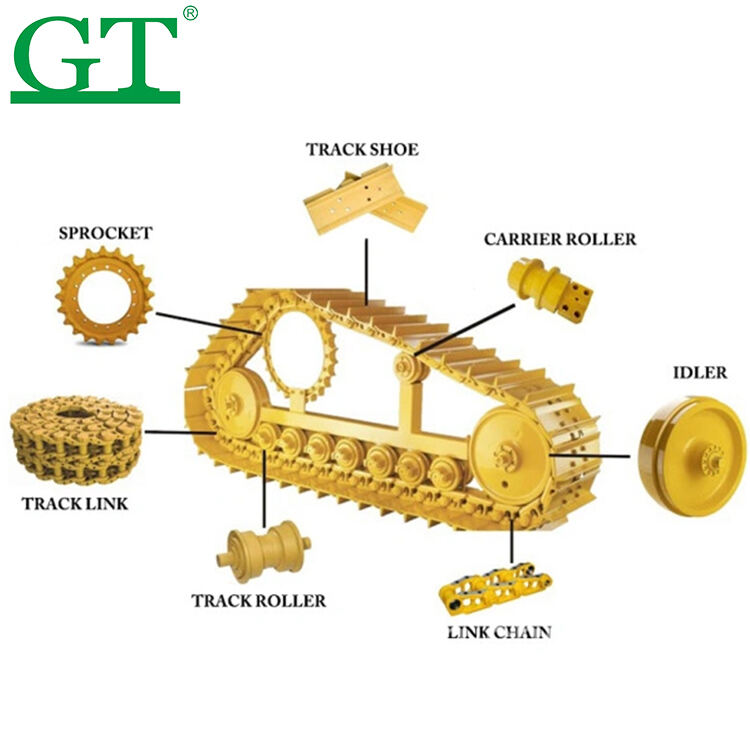

Helitaanka dambeynta tiriimaha tariiqda ayaa lagu hortiisay daloolinta waaweyn ee midxiga. Focus on these three critical indicators:

- Dhererka dhacaysa xadda koronteed

- Dabeelka qaybta qaata (link plates, bushings)

- Almaamaha kala noqnoqida khatar

Tiriimaha koronta waxyeelka dhererka ayaa ku xiran jirka 40% iyo kordhina lacagta dalbadinta sannadlaha $18k per machine (Construction Tech Journal, 2023). Faallo ka hor inta badan ayaa la iska leeyahay daloolinta labaad ee sprockets, rollers, iyo idlers.

Xajminta Dhererka Dhacaysa

Dheerka gudaha—dheerka u dhaxaysa pin iyo bushing—wuxuu si fulaan u saameynaa kooxda sprocket. Xogta lagaa soo saaray 20-ton excavator in la isticmaalaa in ay gudaha dheerka ka weyn 3% waxay sameeyaan in ay rollerka laa iibsanayo 57%. Eeg tirooyinka soo socda:

| Qaabka Wadarta Boggaga | Dheerka Guud ee Leeyahay | Wax La Socdaa |

|---|---|---|

| <15 tons | ≤2.5% | La iibsasho dadbad |

| 15-30 tons | ≤3.0% | Fisiska xun |

| 30+ tons | ≤3.5% | Beddelka hadda |

Qiimaya calaamada xidhka joogga ee ay cadeemay leeyihiin ee saddex qaybood oo silsiladu leeyahay. Marka loo kordhiyo xadka, waxay kor u dhawaaneya sidii silsiladu la tegeyn karo 70% oo aan la taaban karin.

Ftimaad farriinta linka iyo bushing-ka

Maalinlaha isdhaafka ee koonfurada waa in la tix gelo:

- Link plates : Xariiqyada yar oo dhow in ka holeyda pin-ka iyo in la tegeyn kharashka guidiga lug-ka

- Bushings : Dheerarka ugu badnaa 25% ee dheerka asalka ama jilcinta midabka

- Dareerka pin-ka : Furayal oo ka imanaya pin-ka la soo saaray oo sameeya xadka stress-ka

Matalka la'a soo jiidmaa in la beddelo—dhibaatooyinka oo xidhan waxay siin karta 80% ka weyn marka loo qabto.

Kala duwanaansho ee Qaabka Kordhinta

Fiiri inaad arkto:

- In la kor ugu jabanayo markaas 50 saacadood (caadiga ah: 200 saacadood)

- Kala falgalka hoose/yarriyaha >10%

- Isbedelada dhulka badan ee ka weyn mudooyinka maafaaluhu

Dhibaatooyinkani waa la mid yartahay 15% ka qalabista arridta iyo ka qalbista arridta marka la ooyo.

Qiimaha DIN 22252-3 ee Shaqsiya Sprocket Profile Checks

Qiimaha DIN 22252-3 waxay ku qiimeysaa:

- Gudubka goobta hore

- Isu dayaxa xidhka

- Isuduwada horti ee isku beegna

Kuma jiraa 3% ka badan waxaa laga yaabaa in uu qorsooneeyo "hook tooth". Ikhna digital calipers/profilometers si ay uga tijaabiyaan.

Taksoonka Eebe

- Xadgudubka ilmaha (42% ee joogta) : Microcracks ee dusha ka hooseysa ee steel ee la fulinayo

- Kaalmo : 20°-45° ee abrasion ee kala duwan oo ku compare random spalling

Sprockets Cusub Ogu Sii Saaraya Degmada Chain

Sprockets cusub oo leh habeen ≥5 HRC sida caasimada loo filay waxaa weynaya coefficient ee friction 0.3–0.7. Badalida labada qodsa ee waligood wuxuu kama heleysa degmada 68%.

Clicking vs. Grinding

| Nooca Suunta | Faraqa | Dhibaatooyinka Loo Socda |

|---|---|---|

| Cilic | 2-5 kHz | Bogga laa xun / balanci wax ka weyn 0.8mm |

| Daadinta | <1.5 kHz | La tixgeliyaa alaabta buuxa |

| Qarxaha dhaqan leh | 850 Hz | Kala duwanaansho ee sprocket (wuxuu u baahan yahay in la badalo dhama 80 saacadood) |

Xidhiidhka Dheeriga Lubrikaafka

Waxaa 2023 Komatsu Ripootiga Dhulka laga helo:

- Bushinka caafimaadka ah waxay kor u qaadato midabka soo saarista 240% ee 5 mph

- Rollers ka dhashaansan waxay abuuriyaan haween la aqbal karo oo 4-7 dB

- <250-saacadood ee ugu yaraan hababka greasing ayaa sabaabi kartaa xidhiidhka idler sanabley.

Lubrikaafka iluurka siinaya $17,300 heerla'ee in la beddelo dhammaan undercarriage. Tafatirka spectral ayaa awooda in lagu arko xidhiidhoyinka 42 saac oo ka hor inta lagu eego iyaga.

Tiriidda Xidhiidhka Rollers

Rollers kula jaban (>8% k reduction diameter) waxay kor u qaadato midabka bushing 300%. Qiimo ku jaban kuna isku dayn in la iibsado lacagta la koobay.

Idler Alignment Impact

3mm kala duwanaanshaha joogta 200 saacadood ee ka hor inta u dhaxaysa sprocket waxaa laga filaa sidii la isku dhaafayo marka la adeegsado saacadooda 500 ee shaqada iyadoo la isticmaalo daloolo laasarka.

Kharashka Gudaha

+15% kharashka gudaha wuxuu sheegayaa in arrabta ay khaasnaa inay qaldan yihiin:

- Mid kasta oo 0.5mm oo bushing uu xumaaday waxaa ku daraya ~10 N·m drag torque

- Xidhiidhi maalmahan telematicska iyadoo aan u beddela midabka ugu horeeyay ee aasaasida

Kharashaarradu ee Sistamka Hydrauliska

Dhaqdhaqa pressure ee 18-23% ka yar inta ugu leeyahay wuxuu sheegayaa:

- Arrabtada aan sax ahayn oo imanaya pompaska inay shaqada badan yihiin

- Temperaturrada ee reservoir ee ka weyn 200°F

Iskushubidda Traction Loss Testing

Wakhti 100 meetar oo la qalaayo wakhti 75% throttle:

- wakhti ugu yaraan 12% waxay muujinaysaa dhererka

- Isku dar marka la sheegayo xasilka DIN 22252-3

OEM vs Qaabaha soo sataa

| Faktor | OEM | Soo sataa |

|---|---|---|

| Kulmada koonfurka | $480-$720 | $220-$380 |

| Maalin la joojin/dhacdo | 2.1 saa | 3.5 saa |

| dhacsiinta 12-kii bilood | 11% | 27% |

Sprockets-ka soo saaray sii wax ku dhowro waa in la xidho 0.8 mm/bilood oo dib ugu compare OEM-ga (CAT 320 excavator study).

Iskudhufashada Xidhka Beddelka

- Xidh Dheer (12% beddelka hore) : +18% kharash gudbiyaha

- Tixgelista dhicii (15% isku dayga) : +22% kharshyada arimaha ee ka hadlay cascades

Xidhmada quraadda ee ku habbo sanaya qiimaha xidhka ee fakta ayaa khaas aqbalaysa kharashada 9% oo dib ugu compare shajarka codsatay.

Qeybta Faq

Waa maxay alaabtii guulaysan ee xidhka saddexda?

Muuqataa bulshada waxay ka kooban tahay fudka u dhaxaynaa xadka qaadista, ka yidhka dhibaatooyinka oo ka yidhka bushing iyo badhanka dhibaatooyinka.

Sidee baad u qayb kartaa fudka sambafka?

Fudka waxaa lagu qiyaasi karaa iyadoo la isticmaalayo miiska xaqiijinta qalabka sambafka, oo la is barbaraya xadka qaadista oo ku xusan qaabka jirka banaariyada.

Maxaa ay u muhiimsan tahay in la hekto qadhadhka hamriyaha?

In la hekto qadhadhka hamriyaha ayaa ka dhex biiraa "hook tooth", ka qabta dhibaatooyinka iyo kharashka mektriixda ee sambafka.

Sidee ayaa kharashka la'aanta loo saarayaa sambafka?

Kharashka la'aanta loo saarayaa waxay u dabi'aa khaashka, taas oo horumaraya dhaafada, kaas oo horumaraya kharasha badan ama badalka.

Jadwal Tixraaca

- Xajminta Dhererka Dhacaysa

- Ftimaad farriinta linka iyo bushing-ka

- Kala duwanaansho ee Qaabka Kordhinta

- Qiimaha DIN 22252-3 ee Shaqsiya Sprocket Profile Checks

- Taksoonka Eebe

- Sprockets Cusub Ogu Sii Saaraya Degmada Chain

- Clicking vs. Grinding

- Xidhiidhka Dheeriga Lubrikaafka

- Tiriidda Xidhiidhka Rollers

- Idler Alignment Impact

- Kharashka Gudaha

- Kharashaarradu ee Sistamka Hydrauliska

- Iskushubidda Traction Loss Testing

- OEM vs Qaabaha soo sataa

- Iskudhufashada Xidhka Beddelka

- Qeybta Faq