#704, Nr. 2362, Via Fangzhong, Xiamen, Fujian, Sinus, 361009 +86-18350098686 [email protected]

Ad reponendum loricam calceamentorum magnarum excavatorum et dozerum, ut operis vitam multum prolonget. Cum standardibus completis, applicabilis ad omnes magnas excavatores et dozers ad reparandum loricas calceamentorum.

Virga stridens est componentis metallicus communiter inveniendus in machinis gravibus, sicut raptoribus et cingulis onerantibus. Adnectitur calceamentis cingulorum et iuvat tracionem et adprehensionem melius fieri per tergendum terram. Virgae stridentes sunt necessariae ad perficiendum operationem machinae in terris difficilibus, sicut humus laxa vel declivia proniora. Veniunt in varias formas et magnitudines ut aptentur applicationibus diversis et possunt substitui cum sunt usi ut optima functionalitas servetur.

Sunt plures generum virgarum stridentium disponibiles, quaeque designatae sunt pro applicationibus specificis et conditionibus terrarum. Quaedam genera communi modo includunt:

1. Unicus-barra grouser: Hic typus unam barram habet quae bonam trahit et stabilitatem in mollioribus terris sicut lutum, nix, et harena praebet.

2. Duplex-barra grouser: Cum duabus parallelis barris, hic typus maiorem trahit et stabilitatem offert, idoneus est ad difficiliores terras sicut saxosae vel inaequales superficies.

3. Triplex-barra grouser: Tres barras habens, hic typus maximam trahit et stabilitatem praebet, idoneus est ad exigeas terras sicut clivia acerba et aspera terrarum facies.

4. Extremus-usus grouser: Haec gravia usus barrae ad extremas conditiones et gravem machinamentum descripta sunt, superbam trahit et durabilitatem offerebunt.

Cum eligis grouser barra, importantissimum est ut terram et condiciones speciales in quibus erit usus consideres ut optimam operationem certus sis.

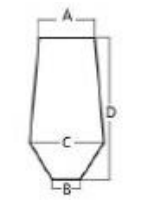

| SECTIO | A mm | B mm | C mm | D mm | Longitudo (mm) | P (KG) |

| 225 | 15 | 8 | 19 | 18 | 225 | 0.51 |

| 335 | 20 | 10 | 24 | 21 | 335 | 1.13 |

| 594 | 28.5 | 12.5 | 36.5 | 64 | 594 | 9.4 |

| 610 | 7 | 5 | 22 | 40 | 610 | 2.8 |

| 910HT-558 | 28.575 | 12.7 | 38.1 | 63.5 | 558 | 9.04 |

| 911HT-558 | 26.987 | 12.7 | 41.275 | 82.55 | 558 | 11.55 |

| 911HT-610 | 26.987 | 12.7 | 41.275 | 82.55 | 610 | 12.7 |

| ACORK3 | 10.17 | 6.35 | 19.05 | 31.75 | 76.2 | 0.28 |

| D10 | 27 | 14 | 36 | 68 | 610 | 10 |

| D10-558 | 28.58 | 14.29 | 38.1 | 66.675 | 558 | 9.5 |

| D10-610 | 28.58 | 14.29 | 38.1 | 66.675 | 610 | 10.4 |

| D11 | 27 | 14 | 41 | 82.5 | 711 | 15.2 |

| D12-610 | 34.925 | 12.7 | 44.45 | 76.2 | 610 | 13.8 |

| D7-508 | 16 | 7.94 | 19 | 35.5 | 508 | 2.5 |

| D8-508 | 19.05 | 9.525 | 25.4 | 50.8 | 508 | 4.4 |

| D9-558 | 24.1 | 7.94 | 33 | 50.8 | 558 | 6.1 |

| D9-610 | 24.1 | 7.94 | 33 | 50.8 | 610 | 6.6 |

| ECORK4 | 10.17 | 7.52 | 19.41 | 38.2 | 76.2 | 0.34 |

| KCORK-4.25″ | 14.3 | 9.5 | 19.1 | 31.75 | 108 | 0.44 |

| SCORK-4.25″ | 25.4 | 7.9 | 28.6 | 50.8 | 108 | 1.1 |

| TCORK-4.25″ | 25.4 | 6.4 | 28.6 | 38.1 | 108 | 0.84 |

Materies : 65Mn Durescentia : HB300~HB320 Longitudo personalis, max 6000mm

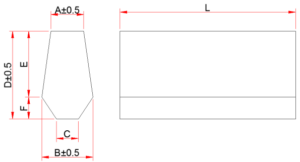

| Numerus partis | A | B | C | D | E | F | L | P (KG) |

| BAR-C-3 | 14.3 | 22.2 | 9.53 | 38.11 | 28.58 | 9.53 | 76.2 | 0.405 |

| BAR-K-4 | 14.3 | 19.1 | 9.53 | 31.76 | 34.93 | 9.53 | 101.6 | 0.4075 |

| BAR-L-3 | 11.1 | 15.9 | 6.35 | 25.4 | 19.05 | 6.35 | 76.2 | 0.1974 |

| BAR-E-3 | 9.5 | 19.1 | 7.94 | 38.1 | 31.75 | 6.35 | 76.2 | 0.325 |

| BAR-A-3 | 9.5 | 15.9 | 6.35 | 34.93 | 28.58 | 6.35 | 76.2 | 0.261 |

Materies : 40Cr Duritas : HB500 Funditio et Performatio Caloris necessaria.

| Numerus partis | A | B | C | D | E | F | L | P (KG) |

| ECORK 3 | 9.5 | 19.1 | 7.94 | 38.15 | 31.8 | 6.35 | 76.2 | 0.326 |

| GCORK 4 | 14.3 | 25.4 | 9.53 | 44.46 | 34.93 | 9.53 | 101.6 | 0.69 |

| JCORK 4 | 19.1 | 28.6 | 9.53 | 60.3 | 49.2 | 11.1 | 101.6 | 1.11 |

| ACORK 3 | 9.5 | 15.9 | 6.35 | 31.7 | 25.4 | 6.35 | 76.2 | 0.237 |

| WCORK 2.5 | 8 | 14.3 | 6.5 | 19.1 | 13.92 | 5.18 | 63.5 | 0.105 |

| KCORK 4 | 14.3 | 19.1 | 9.53 | 31.76 | 22.23 | 9.53 | 101.6 | 0.405 |

| HCORK 4 | 15.9 | 25.4 | 9.53 | 52.39 | 41.28 | 11.11 | 101.6 | 0.835 |

| CCORK 3 | 14.3 | 22.2 | 9.52 | 38.1 | 28.58 | 9.52 | 76.2 | 0.405 |

Materies: 42CrMoNi Durescentia: HB500-550 Fundus et percalescitio necessarii.

| Numerus partis | A | B | C | D | E | F | L | P (KG) |

| D9-610 | 24.1 | 33 | 7.94 | 50.8 | 41.28 | 9.53 | 610 | 6.6 |

| D10-610 | 28.58 | 38.1 | 14.29 | 66.68 | 57.15 | 9.53 | 610 | 10.4 |