How the Track Adjuster Cylinder Maintains Optimal Track Tension

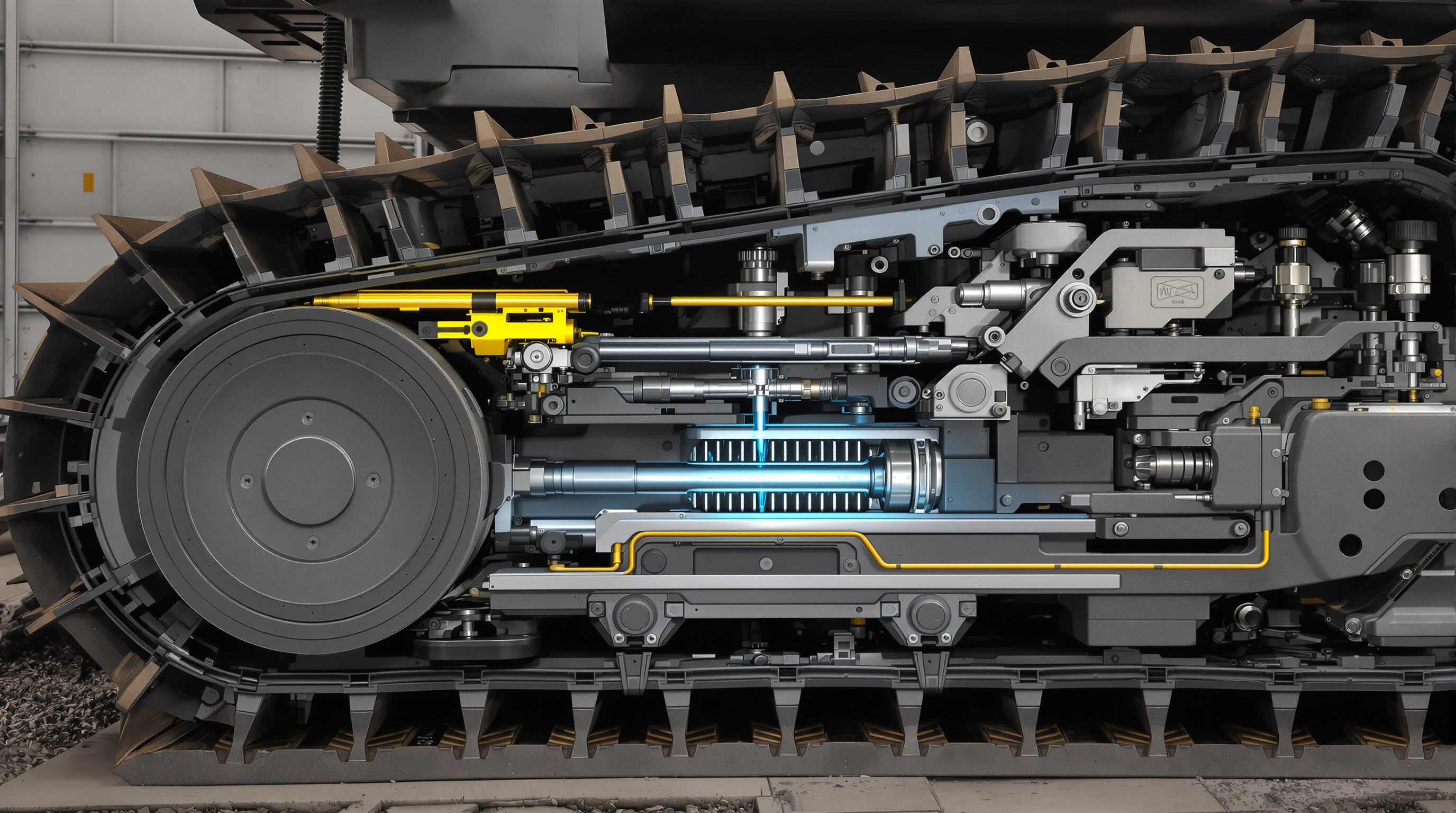

The track adjuster cylinder in undercarriage systems acts as the primary regulator of track tension, ensuring heavy machinery operates safely and efficiently across diverse terrains. By balancing hydraulic forces with mechanical precision, this component prevents track slippage, reduces premature wear, and extends undercarriage lifespan.

Principle of Operation: Regulating Tension via Hydraulic Pressure

The hydraulic pressure pushes on the adjuster cylinder's piston, which either compresses or lets go of the internal recoil spring inside. What happens next? The idler wheel gets pushed forward or pulled back depending on what's needed for proper track tension. If the tracks start getting too slack, the system pumps in some hydraulic fluid to push out the piston and tighten things up. On the flip side, when there's too much tension, it releases fluid through a valve built into the cylinder itself. Pretty impressive actually this whole setup reacts pretty fast too about 10 seconds max when conditions change on the ground. And best part? It keeps everything right around plus or minus 10 percent from what the manufacturers recommend for optimal performance.

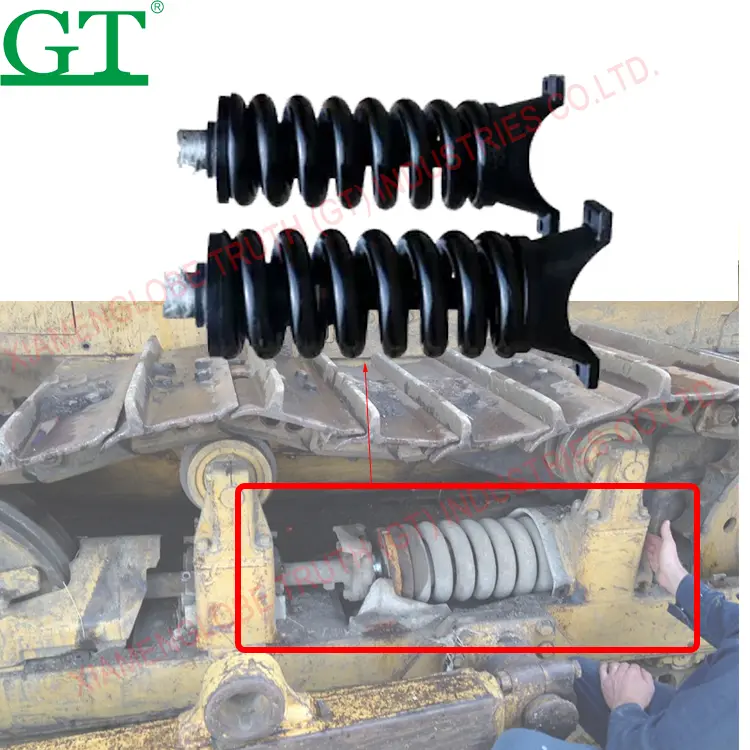

Key Components of the Track Adjuster Cylinder and Their Functions

Four elements work synergistically:

| Component | Function | Failure Impact |

|---|---|---|

| Cylinder Body | Contains hydraulic fluid at 3,000 PSI | Fluid leaks reduce tension precision |

| Chromium Plated Piston | Transmits hydraulic force | Scratches >0.5mm depth cause pressure loss |

| Dual-Coil Recoil Spring | Absorb shocks up to 12G force | Fatigue cracks increase derailment risk by 40% |

| Nitrile Seals | Prevent contamination ingress | 78% of track failures start with seal degradation (NORS 2023 data) |

Integration with the Idler Wheel and Undercarriage System

The cylinder connects directly to the idler wheel through a tension rod, forming a closed-loop feedback system:

- Track slack increases during operation — sensor detects tension drop

- Hydraulic pump activates — piston extends — idler pushes track outward

- Recoil spring maintains constant force during load fluctuations

This integration reduces sprocket wear by 32% compared to manual tensioning systems (Journal of Construction Engineering, 2023).

The Impact of Proper Track Tension on Equipment Performance and Component Longevity

Maintaining optimal track tension through the track adjuster cylinder is essential for balancing operational efficiency with long-term undercarriage durability. This equilibrium directly impacts fuel consumption, component wear rates, and machine stability across diverse terrains.

Enhanced Excavator Efficiency Through Consistent Track Tension

Proper tension reduces rolling resistance by 12–18% (Construction Equipment Research Institute 2023), enabling smoother operation and lower fuel consumption. When tension aligns with manufacturer specifications, hydraulic systems work less strenuously to maintain track engagement with sprockets and idlers. This precision minimizes energy waste while improving maneuverability on slopes and uneven surfaces.

Reducing Wear on Tracks, Rollers, and Sprockets with Optimal Tension

Correct tension distribution prevents three primary failure patterns:

- Track Link Wear: Over-tensioning increases bushing surface stress by 22–35%

- Roller Fatigue: Under-tensioning causes irregular load distribution across carrier rollers

- Sprocket Tooth Degradation: Improper tension accelerates tooth rounding in high-torque applications

Field data from aggregate mining operations shows properly tensioned systems reduce quarterly roller replacement rates by 41% compared to poorly adjusted counterparts.

Data-Driven Evidence: Proper Tension and Extended Undercarriage Life

A 3-year study tracking 217 excavators demonstrated:

| Tension Precision | Avg. Undercarriage Life | Annual Repair Cost Reduction |

|---|---|---|

| ±5% Specification | 8,200 hours | 29% |

| ±15% Specification | 5,700 hours | 12% |

Machines maintaining tension within 5% of OEM targets required 37% fewer track adjuster cylinder replacements over their service life, validating the critical relationship between tension accuracy and component longevity.

Common Failures and Symptoms of a Deteriorating Track Adjuster Cylinder

Hydraulic Fluid Leaks and Seal Degradation: Early Warning Signs

When hydraulic fluid starts leaking around the track adjuster cylinder, it usually means the seals are failing. This leads to poor tension control and makes parts wear out faster than normal. Bad seals let dirt and debris get into the hydraulic system, which messes with lubrication and creates extra friction between moving parts. Anyone operating these machines needs to fix leaks as soon as possible before track sag gets beyond the 2 inch limit. Going past that point puts serious strain on both the idler wheels and sprocket assembly, leading to costly repairs down the road.

Unusual Noises, Vibration, and Track Misalignment Issues

A failing adjuster cylinder manifests through three primary symptoms:

- Grinding or knocking sounds from uneven piston movement

- Vertical play in tracks exceeding manufacturer specifications

- Lateral misalignment causing uneven wear patterns on rollers

These issues correlate with a 37% increase in undercarriage replacement costs (Equipment Maintenance Quarterly 2023) when left unresolved for over 500 operating hours.

Spring Failure and Internal Damage in High-Stress Environments

The constant pounding from mining operations or construction work takes a toll on those coil springs inside the adjusters, making them progressively weaker at holding that basic tension level they need. When things get too tight in these environments, all sorts of problems start showing up. The piston rods get scratched up by tiny abrasive particles floating around. The cylinder barrels start to deform after going through thousands of pressure cycles exceeding 3,000 psi. And don't even get me started on what happens to hardened steel parts when hydrogen gets into the mix causing embrittlement issues. For folks working near coastlines or in areas with strong chemicals present, the situation is even worse. According to recent findings from the Heavy Machinery Longevity Report published last year, these operators experience spring failures at almost twice the rate compared to others just because of saltwater damage and ongoing chemical attacks.

Risks of Ignoring Track Tension: Derailment, Downtime, and Costly Repairs

Over-Tensioned Tracks and Premature Component Wear

When a track adjuster cylinder starts to fail, it creates way too much tension that ends up putting all sorts of uneven pressure on various components like rollers, sprockets, and those little idler wheels. According to some research done in 2022 about undercarriage wear, when tracks get too tight they actually speed up the wear process by around 25-30%. The sprocket teeth begin to bend out of shape after just about 800 hours of operation. And there's another problem too. All this extra strain makes machines burn through fuel at a higher rate, somewhere between 9% and maybe even 12% more, because the hydraulics have to work harder to overcome all that additional friction.

Under-Tensioned Tracks Leading to Track Derailment: Mining Case Insight

When tracks get loose because the hydraulic pressure isn't right or springs give out, this really increases the chance of derailments happening, especially when the ground is bumpy. According to the latest Mining Equipment Report from 2023, about one third of all track derailments in quarries happened when the tension was too low. And these incidents don't just stop work they also cost around fourteen thousand dollars each for repairs and lost time. For those operating machines in muddy conditions or snowy areas, checking track tension becomes pretty much a must do thing. Most experienced operators will tell you they check their tracks at least three times every day to stop them from slipping sideways, which can be a real nightmare in tough terrain.

Financial Impact: Rising Downtime Costs from Poor Tension Management

Ignoring tension adjustments leads to cumulative expenses:

- Downtime: $740,000 annual losses per fleet (Ponemon 2023) from derailment-related stoppages

- Component Replacements: Premature roller/sprocket wear adds $18,000–$22,000 per machine in 5-year maintenance

- Labor: Emergency repairs demand 15–20 technician hours versus 2 hours for scheduled adjustments

Proactive monitoring of the track adjuster cylinder and adherence to OEM tension specs reduce undercarriage replacement cycles by 40%, according to undercarriage maintenance guidelines.

Best Practices for Maintaining Track Adjuster Cylinder Longevity

Routine Inspection Checklist for Early Failure Detection

Weekly inspections of the track adjuster cylinder are critical for identifying early signs of wear. Focus on:

- Hydraulic seals: Check for fluid leaks, which account for 38% of cylinder failures (Hydraulic Systems Study 2023).

- Track alignment: Measure tension using manufacturer-recommended tools to prevent uneven loading on rollers and sprockets.

- Debris buildup: Remove hardened mud or rocks trapped near the idler wheel, a leading cause of misalignment.

Proactive Maintenance and Hydraulic System Care

Scheduled fluid changes every 500 operating hours reduce contaminants that degrade cylinder seals. Pair this with:

- Greasing intervals: Lubricate pivot points every 50 hours in high-dust environments.

-

Component upgrades: Install reinforced piston rods in abrasive conditions to minimize scoring damage.

Always use OEM-compatible hydraulic fluids to maintain viscosity ratings under extreme temperatures.

Predictive Maintenance Strategies to Reduce Long-Term Costs

Advanced monitoring systems cut repair costs by 22% compared to reactive approaches (2023 Construction Equipment Reliability Report). Implement:

| Strategy | Benefit | Implementation Frequency |

|---|---|---|

| Vibration sensors | Detects internal cylinder wear | Real-time monitoring |

| Pressure decay testing | Identifies seal leaks before failure | Quarterly |

| Oil analysis | Flags fluid contamination early | Every 250 operating hours |

These methods extend the track adjuster cylinder’s service life while optimizing undercarriage performance across load cycles.

FAQ

What is a track adjuster cylinder?

The track adjuster cylinder is a component of heavy machinery’s undercarriage system. It maintains optimal track tension by regulating hydraulic pressure, preventing track slippage and premature wear.

Why is track tension important in heavy machinery?

Proper track tension ensures machinery operates efficiently, prevents excessive wear on components like rollers and sprockets, and helps in reducing fuel consumption.

What happens if track tension is not maintained?

Ignoring proper track tension can lead to track slippage, derailment, increased wear on machinery components, and higher maintenance costs.

What are the symptoms of a failing track adjuster cylinder?

Symptoms include hydraulic fluid leaks, unusual noises, vibrations, track misalignment, and inefficient performance across terrain.

How often should track tension be checked?

Track tension should be checked routinely, often multiple times a day, especially during operations in challenging terrains like mud or snow.

Table of Contents

- How the Track Adjuster Cylinder Maintains Optimal Track Tension

- The Impact of Proper Track Tension on Equipment Performance and Component Longevity

- Common Failures and Symptoms of a Deteriorating Track Adjuster Cylinder

- Risks of Ignoring Track Tension: Derailment, Downtime, and Costly Repairs

- Best Practices for Maintaining Track Adjuster Cylinder Longevity

- FAQ