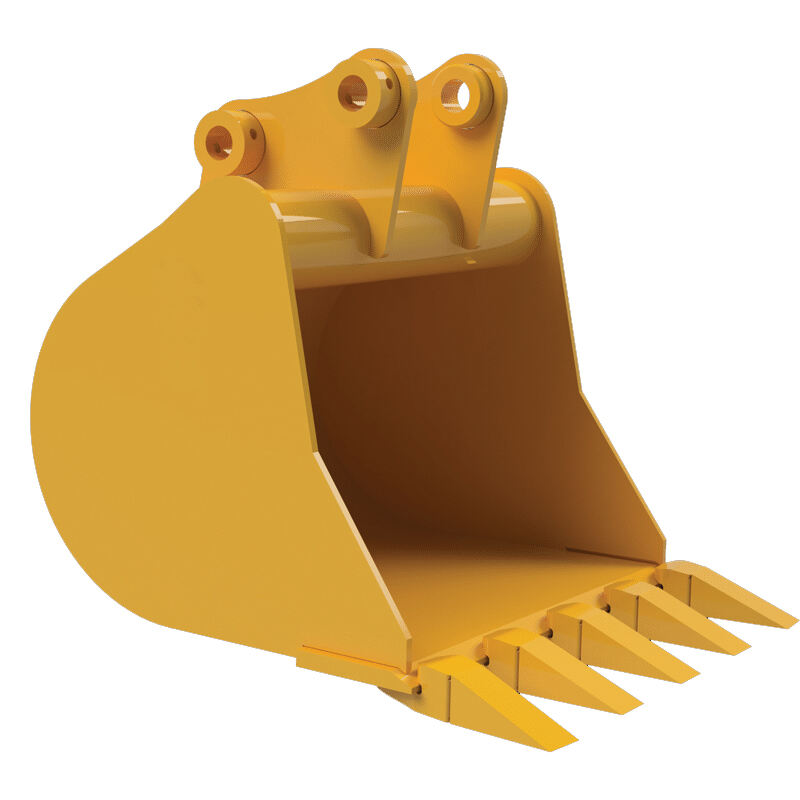

The locking force is strong, and the bucket teeth are never loose

Forged with high hardness steel, it can firmly clamp the bucket teeth, even when excavating hard rock strata or frozen soil, it will not appear loose, shaking. There is no need for frequent shutdown inspection during construction, which saves a lot of trouble.