#704,No.2362,Fangzhong Road,Xiamen,Fujian,China,361009 +86-13860439542 [email protected]

Understanding the core value of an excavator track tensioner: far more than just a standard spare part

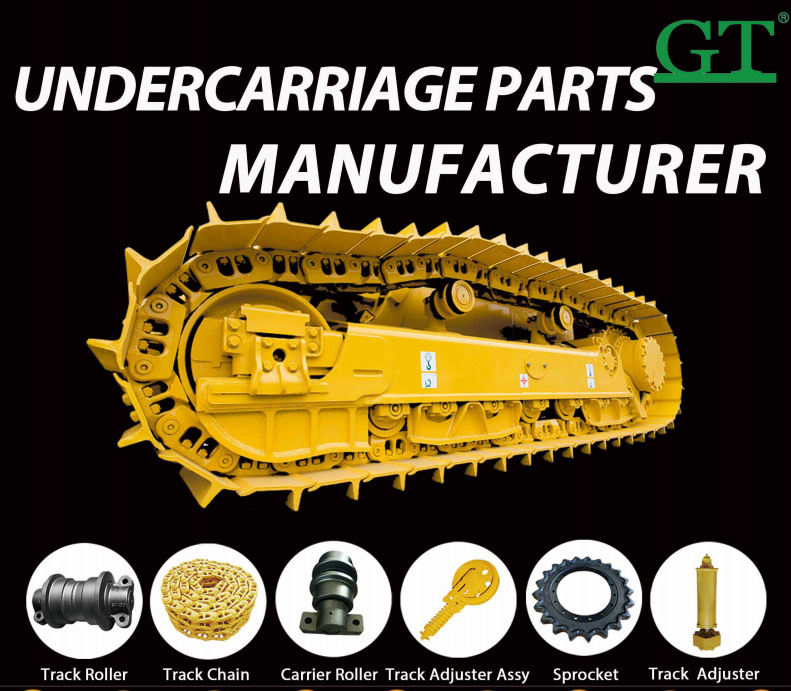

Within the large and complex structure of an excavator, the track tensioner (also known as a track adjuster or tension cylinder) is often overlooked, yet its role is central, directly impacting the stability, safety, and operational profitability of the equipment. This is far more than a simple replacement part; it is the cornerstone ensuring your equipment's normal mobility, operational efficiency, and overall economic benefits.

Imagine the consequences of loose tracks: they significantly increase the risk of catastrophic track detachment when operating on steep slopes, rugged terrain, or muddy surfaces. This not only leads to costly downtime but also poses serious on-site safety hazards. The track tensioner is the key defense against this issue. It uses internal hydraulic pressure to precisely maintain track tension, ensuring a secure engagement between the track links, guide wheels, and idler wheels, effectively preventing derailments and safeguarding operational continuity and personnel safety.

However, its significance extends far beyond preventing derailments. The track tensioner is a core element in extending the lifespan of valuable undercarriage components. Incorrect tension—whether too loose or too tight—can cause wear rates on undercarriage components (such as track links, idler wheels, track rollers, drive sprockets, and even travel motors) to increase exponentially. A loose track can cause the “whiplash effect,” violently impacting the guide wheels and excessively stretching the track links; conversely, an overly tight track can excessively compress the undercarriage rollers, bushings, and travel motor components. A properly functioning tensioner dynamically maintains the “optimal tension point,” keeping stress on components within reasonable limits and significantly extending their lifespan. In short, promptly replacing a tensioner at a reasonable cost is often the most economical solution to prevent the entire undercarriage system—which may cost several or even ten times more—from failing prematurely.