How Hydraulic Cylinders Work: Core Principles and Key Components

The Basic Principle of Fluid Power in Hydraulic Cylinders

The operation of hydraulic cylinders relies heavily on what we call Pascal's Principle. Basically, when pressure gets applied to a fluid that's trapped inside something, that pressure spreads out evenly everywhere in the system. So here's how it works in practice: pressurize some hydraulic fluid within a sealed container, and suddenly there's force pushing against a piston. The result? Linear movement that makes these cylinders so powerful. And let's put this into perspective for a moment. Take a standard 2 inch diameter cylinder for instance. Hook it up to 1000 pounds per square inch of pressure, and boom! We're talking about well over six thousand pounds of lifting capacity right there. That kind of power output explains why hydraulics remain such a staple across so many industrial applications.

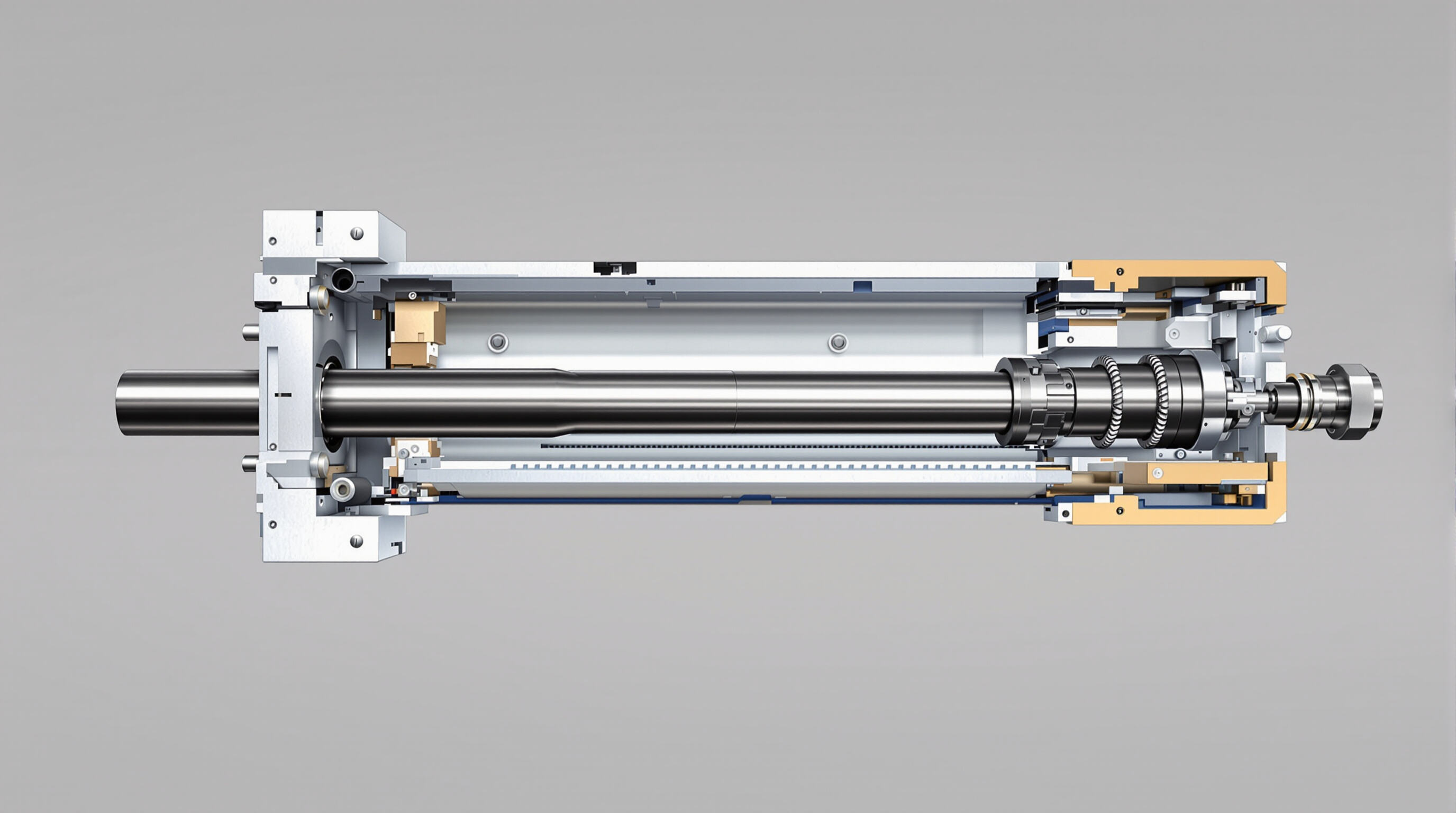

Essential Components: Piston, Rod, Barrel, and Seals

Four core components allow hydraulic cylinders to convert fluid energy into mechanical movement:

- Piston: Divides the cylinder into chambers and transfers force to the rod

- Rod: Transmits mechanical force to external machinery

- Barrel: Houses the pressurized fluid and withstands operating pressures up to 5,000 PSI in industrial models

- Seals: Prevent leakage while enduring extreme temperatures from -40°F to 250°F

Durable materials like chromium-plated rods and nitrile seals are commonly used in construction equipment to resist wear and contamination, ensuring long service life.

The Role of Hydraulic Fluid in Force Transmission and System Efficiency

The right hydraulic fluid, usually ISO VG 32 or 46 grades, does three main things for systems. First off, it transfers power while wasting as little energy as possible. Second, it keeps all those moving parts properly lubricated so they don't wear out too fast. And third, it helps get rid of heat by circulating through the reservoir system. Maintenance matters a lot here since most hydraulic problems come from bad fluid conditions. Keeping the viscosity where it should be and getting rid of particles smaller than 10 microns makes sure pressure moves efficiently through the system. This kind of care also means components last longer before needing replacement or repair.

Main Types of Hydraulic Cylinders: Single-Acting, Double-Acting, Tie-Rod, and Welded

Single-Acting vs. Double-Acting Cylinders: Functionality and Use Cases

Single acting cylinders work by pushing the piston out using hydraulic pressure, then depend on either springs or gravity to bring it back into place. These types are commonly found in straightforward equipment where complexity isn't needed, think dump trucks that tilt cargo beds or basic hydraulic presses used in workshops. Now when we talk about double acting cylinders, things get a bit different. Both ends of the piston receive pressure, so operators can control movement in either direction with much better precision. That kind of control is why these show up everywhere from factory assembly lines to heavy duty construction gear like excavators digging through tough terrain. And there's actually some pretty good math behind this too - tests have shown that double acting models generally deliver around 20 percent more force efficiency during those back and forth movements compared to their single acting counterparts.

Tie-Rod Cylinders: Cost-Effective Solutions for Industrial Applications

Tie rod cylinders have those threaded steel rods holding the end caps in place, which makes assembly modular and fits right into NFPA size requirements. The way these cylinders are built lets technicians take them apart pretty fast using just standard tools, cutting down on maintenance time during production runs maybe around 40% give or take depending on the situation. Most models can handle pressures below 3,000 psi, but what really keeps them popular across industries like material handling and plastic injection molding is how affordable they are compared to other options. Parts tend to swap out easily too. These cylinders usually run about 30% cheaper than welded versions that carry similar loads, making them a smart choice when budget matters without sacrificing too much performance.

Welded Cylinders: Built for Durability in Heavy-Duty Environments

When it comes to welded cylinders, the barrel gets permanently attached to those end caps using either arc or laser welding techniques. This means no more worrying about those pesky tie-rods becoming weak spots over time. The sturdy build can take on pressure surges exceeding 5,000 PSI and stands up pretty well against impacts and vibrations too, which is why they work so great in tough industries like mining operations and rail systems. What makes these cylinders stand out is how their solid construction reduces rod bending when subjected to sideways forces. That's exactly what makes them a good fit for things like hydraulic shears used in scrap yards or forestry equipment that gets put through its paces daily. According to some field tests we've seen, these welded versions tend to stick around about half again as long as other types in really harsh conditions found on quarry conveyor belts and offshore drilling rigs.

Critical Applications of Hydraulic Cylinders Across Industries

Construction Machinery: Excavators, Loaders, and Cranes

Construction equipment relies on hydraulic cylinders to deliver that controlled pushing and pulling action we need on job sites. Take excavators for instance they have these double acting cylinders working hard behind the scenes to move the boom, arm, and bucket around even when things get bumpy. Loaders work similarly but with multiple cylinders arranged just right so operators can position buckets at different angles without missing a beat. And let's not forget tower cranes those giants standing tall on city skylines use specially designed cylinders that can lift stuff weighing way more than most people can imagine (over 50 tons actually) while staying steady even when the wind starts blowing pretty hard. All these hydraulic systems give workers amazing control down to almost exact measurements when doing complicated tasks day after day.

Mining and Heavy Haul Equipment: Drilling Rigs and Haul Trucks

The telescopic hydraulic cylinders used in drilling rigs can push through bedrock with force exceeding 200 tons. These systems come equipped with reinforced steel rods and specially designed seals that stand up against the harsh abrasive slurry common in mining operations. When it comes to haul trucks, we see double stage cylinders at work managing how the dump beds move, handling loads that often go past 400 tons without issue. Built to handle really tough environments, these components keep working even when temperatures swing between minus 40 degrees Fahrenheit and as high as 250 degrees. They also withstand intense vibrations during blasting operations that reach well beyond 15g forces. The secret? Solid welding throughout their construction makes them durable enough for continuous operation in some of the harshest industrial settings around.

Agriculture and Rail: Tractors, Harvesters, and Door Actuation Systems

Today's farm equipment makes extensive use of hydraulic cylinders for critical functions. Tractors commonly employ these components to fine tune the pressure applied by implements when working through fields, whereas modern harvesters need carefully coordinated cylinder arrangements to keep their cutting bars level across rough ground conditions. Agricultural cylinders get coated with special materials that stand up against harsh chemicals found in fertilizers and pesticides. When it comes to railway applications, space saving hydraulic units handle door operations at impressive pressures reaching around 5000 pounds per square inch. These systems feature specially designed seals that continue working properly well beyond 100 thousand operational cycles despite dirt and grime tracked in from outside. Manufacturers also build in water resistant features so trains can keep running smoothly even during heavy rainstorms or flooding events that would otherwise disrupt service.

Key Benefits of Hydraulic Cylinders in Industrial and High-Force Applications

Superior Precision and Control in Manufacturing Processes

The reason hydraulic cylinders deliver such fine control in industrial automation has everything to do with how hydraulic fluid doesn't compress easily. This property lets them maintain steady force and speed even when dealing with changing loads throughout production processes. We see these cylinders all over the place in critical manufacturing areas like CNC machines, semiconductor fabrication plants, and precision welding operations. A tiny mistake at this scale can actually cause major problems down the line for finished products. Mechanical alternatives tend to suffer from something called backlash, which creates unwanted movement between parts. Hydraulics avoid this issue completely by adjusting pressure as needed. According to recent industry data from the International Fluid Power Society, some systems can achieve positioning accuracy as tight as 0.01 millimeters, though actual results depend on system design and maintenance practices.

High Force Output and Efficiency in Low-Speed Operations

Hydraulic cylinders pack a real punch when it comes to force output, generating up to ten times more power than pneumatic systems occupying similar space while still working efficiently even at very slow speeds. These systems work great in heavy duty situations such as press brakes that need over 500 tons of pressure or conveyor belts where controlled movement is critical. Take a look at the numbers: hydraulic systems have around 1 kW per kilogram of power to weight ratio, which beats electric actuators hands down since they only manage about 0.2 kW per kg. That means hydraulic setups actually waste about 35 percent less energy when running continuously at lower RPMs. Plus, the fact that the fluid inside these systems naturally lubricates components while also carrying away heat makes them run better when pushed to their limits.

Hydraulic vs. Electric Actuators: Understanding the Trade-offs

Choosing between hydraulic and electric actuators depends on application demands:

- Force Requirements: Hydraulics excel above 25 kN; electric is better suited for lighter, high-cycle tasks

- Environmental Conditions: Hydraulic systems perform reliably from -40°C to 200°C, where electric motors may fail

- Maintenance Complexity: Electric actuators have fewer components, but hydraulics tolerate contamination better

- Precision: Servo-electric actuators offer finer positioning (±5µm), but hydraulics maintain force control when stalled

While electric actuators are preferred in clean-room environments to avoid fluid leaks, hydraulics remain unmatched in high-impact applications like mining shovels and steel mill equipment, where shock loads can exceed 250% of rated capacity.

Selecting and Maintaining Hydraulic Cylinders for Optimal Performance

Choosing the Right Cylinder: Bore Size, Stroke Length, and Mounting Options

When picking out the right cylinder for an application, there are several key factors to consider including bore size, stroke length, and how it will be mounted. The diameter of the bore plays a big role in determining force output. Larger bores definitely produce more force, but they also need more hydraulic fluid to operate properly. Stroke length matters too since it dictates how far the piston can move within the cylinder and impacts what kind of structural support might be needed around it. Most cylinders come with different mounting styles like fixed centerline mounts, pivoting mounts, or flange mounts. Pivoting mounts work well when there's some expected angular movement during operation, whereas fixed mounts help keep things stable and minimize side-to-side forces. Systems that run at pressures over 500 psi tend to benefit from welded tie rod designs instead of standard collar mounts according to real world testing. These welded versions cut down on bending stresses by about a third compared to their counterparts, which makes them worth considering for high pressure applications.

Preventive Maintenance: Avoiding Seal Failure, Corrosion, and Contamination

Proactive maintenance prevents the majority of hydraulic cylinder failures. Key practices include:

- Seal Integrity Checks: Replace rod seals every six months using fluoropolymer seals for extreme temperature resistance

- Corrosion Management: Use phosphate coatings or cathodic protection in wet or corrosive environments

- Contamination Control: Install high-efficiency inline filters (β≥200) and conduct quarterly fluid analysis to meet NAS 1638 Class 7 cleanliness standards

Particulate contamination accounts for 42% of premature wear cases and can reduce cylinder lifespan by 60% without proper filtration. Tracking service cycles helps prevent unexpected downtime in critical operations.

FAQs about Hydraulic Cylinders

What are hydraulic cylinders used for?

Hydraulic cylinders are primarily used to generate linear motion and force in various industrial applications including construction machinery, mining, agriculture, and rail systems.

How does a hydraulic cylinder work?

A hydraulic cylinder works by applying fluid pressure to the piston, enabling it to move and transfer mechanical energy to the rod, resulting in linear motion.

What are the main types of hydraulic cylinders?

The main types of hydraulic cylinders include single-acting cylinders, double-acting cylinders, tie-rod cylinders, and welded cylinders.

How often should hydraulic cylinder seals be replaced?

It is recommended to replace hydraulic cylinder seals every six months to ensure optimal performance and prevent leakage.

Table of Contents

- How Hydraulic Cylinders Work: Core Principles and Key Components

- Main Types of Hydraulic Cylinders: Single-Acting, Double-Acting, Tie-Rod, and Welded

- Critical Applications of Hydraulic Cylinders Across Industries

- Key Benefits of Hydraulic Cylinders in Industrial and High-Force Applications

- Selecting and Maintaining Hydraulic Cylinders for Optimal Performance

- FAQs about Hydraulic Cylinders