#704, 2362-son Fanzhong ko'chasi, Xiamen, Fujian, Xitoy, 361009 +86-18350098686 [email protected]

Кatta экскаваторлар ва дожерлар учун трак шуўасини таъминлаш учун истифода етилади, ишlash муддатини кўпчаравтириш учун. Толий стандартлар билан, кatta экскаваторлар ва дожерлар учун трак шуўасини таъминлаш учун муваффақиятли ривожланган.

Grouser panel bu tomchalik mashinalarga, masalan, buldozerga va traqlarga asoslangan metallik komponent. U traq qaychaqa ulangan va yer bilan bog'lanish va o'tkazma quvvatini yaxshilash uchun foydalaniladi. Grouser panel mashina performansini murakkab turmushda, masalan, noqulay yerda yoki charchaq yo'li ustida yaxshilash uchun muhimdir. Ular turli shakllarda va hajmda bo'lib, talabga ko'ra tanlanadi va xoshimaroq bo'lganda almashtirilishi mumkin.

Turli xil grouser panel turlari mavjud, har biri maxsus muamмолар va turmush shartlari uchun dizayn qilingan. Eng umumiy turlar quyidagilar:

1. Bitta chizgili grouser: Ushbu tur bitta chizgini o'z ichiga oladi, bu esa moddai yo'qlarda, masalan, challoq, qor va qumda yaxshi traksiya va stabillik beradi.

2. Ikki chizgili grouser: Ikki parallel chizgilar bilan, ushbu tur traksiya va stabillikni oshiradi va bu uni to'q bo'lgan yoki tengsiz sirtlar kabi ko'paytirilgan terrordagi ishlatish uchun muodaballashdiradi.

3. Uch chizgili grouser: Uchta chizgini o'z ichiga olgan ushbu tur maksimal traksiya va stabillikni ta'minlaydi va bu uni singgil o'smon va asper sirtlar kabi talab qiladigan terrordagi ishlatish uchun ideal qiladi.

4. Ekstrem mashg'ulot uchun grouser: Bu qattiq mashinalar uchun ekstrem holatlarda dizaynlangan qattiq chizgilar hisoblanadi va ularga superiy traksiya va davomiylik taqdim etiladi.

Grouser chizgini tanlashda unutmangki, optimal performansni ta'minlash uchun uni qanday terrorda va shartlarda ishlatilishi kerakligini o'rganishingiz kerak.

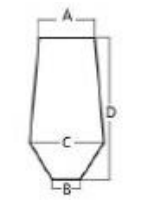

| BO'LIMN | MM | B MM | C MM | D MM | Uzunlik (mm) | W (KG) |

| 225 | 15 | 8 | 19 | 18 | 225 | 0.51 |

| 335 | 20 | 10 | 24 | 21 | 335 | 1.13 |

| 594 | 28.5 | 12.5 | 36.5 | 64 | 594 | 9.4 |

| 610 | 7 | 5 | 22 | 40 | 610 | 2.8 |

| 910HT-558 | 28.575 | 12.7 | 38.1 | 63.5 | 558 | 9.04 |

| 911HT-558 | 26.987 | 12.7 | 41.275 | 82.55 | 558 | 11.55 |

| 911HT-610 | 26.987 | 12.7 | 41.275 | 82.55 | 610 | 12.7 |

| ACORK3 | 10.17 | 6.35 | 19.05 | 31.75 | 76.2 | 0.28 |

| D10 | 27 | 14 | 36 | 68 | 610 | 10 |

| D10-558 | 28.58 | 14.29 | 38.1 | 66.675 | 558 | 9.5 |

| D10-610 | 28.58 | 14.29 | 38.1 | 66.675 | 610 | 10.4 |

| D11 | 27 | 14 | 41 | 82.5 | 711 | 15.2 |

| D12-610 | 34.925 | 12.7 | 44.45 | 76.2 | 610 | 13.8 |

| D7-508 | 16 | 7.94 | 19 | 35.5 | 508 | 2.5 |

| D8-508 | 19.05 | 9.525 | 25.4 | 50.8 | 508 | 4.4 |

| D9-558 | 24.1 | 7.94 | 33 | 50.8 | 558 | 6.1 |

| D9-610 | 24.1 | 7.94 | 33 | 50.8 | 610 | 6.6 |

| ECORK4 | 10.17 | 7.52 | 19.41 | 38.2 | 76.2 | 0.34 |

| KCORK-4.25″ | 14.3 | 9.5 | 19.1 | 31.75 | 108 | 0.44 |

| SCORK-4.25″ | 25.4 | 7.9 | 28.6 | 50.8 | 108 | 1.1 |

| TCORK-4.25″ | 25.4 | 6.4 | 28.6 | 38.1 | 108 | 0.84 |

Material : 65Mn Sirtqi : HB300~HB320 Uzunlik taxallus, jami 6000mm

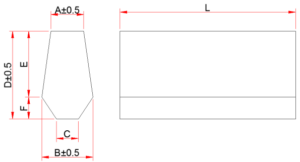

| Qism raqami | A | B | C | D | E | F | L | W (KG) |

| BAR-C-3 | 14.3 | 22.2 | 9.53 | 38.11 | 28.58 | 9.53 | 76.2 | 0.405 |

| BAR-K-4 | 14.3 | 19.1 | 9.53 | 31.76 | 34.93 | 9.53 | 101.6 | 0.4075 |

| BAR-L-3 | 11.1 | 15.9 | 6.35 | 25.4 | 19.05 | 6.35 | 76.2 | 0.1974 |

| BAR-E-3 | 9.5 | 19.1 | 7.94 | 38.1 | 31.75 | 6.35 | 76.2 | 0.325 |

| BAR-A-3 | 9.5 | 15.9 | 6.35 | 34.93 | 28.58 | 6.35 | 76.2 | 0.261 |

Материал: 40Cr, Стойкость: HB500, Литейный процесс ва жармояда керак.

| Qism raqami | A | B | C | D | E | F | L | W (KG) |

| ЭКОРК 3 | 9.5 | 19.1 | 7.94 | 38.15 | 31.8 | 6.35 | 76.2 | 0.326 |

| ГКОРК 4 | 14.3 | 25.4 | 9.53 | 44.46 | 34.93 | 9.53 | 101.6 | 0.69 |

| ЖКОРК 4 | 19.1 | 28.6 | 9.53 | 60.3 | 49.2 | 11.1 | 101.6 | 1.11 |

| АКОРК 3 | 9.5 | 15.9 | 6.35 | 31.7 | 25.4 | 6.35 | 76.2 | 0.237 |

| ВКОРК 2.5 | 8 | 14.3 | 6.5 | 19.1 | 13.92 | 5.18 | 63.5 | 0.105 |

| KCORK 4 | 14.3 | 19.1 | 9.53 | 31.76 | 22.23 | 9.53 | 101.6 | 0.405 |

| HCORK 4 | 15.9 | 25.4 | 9.53 | 52.39 | 41.28 | 11.11 | 101.6 | 0.835 |

| CCORK 3 | 14.3 | 22.2 | 9.52 | 38.1 | 28.58 | 9.52 | 76.2 | 0.405 |

Материал: 42CrMoNi. Күчлуги: HB500-550. Кастанга ва ёримли ишлатиш керак.

| Qism raqami | A | B | C | D | E | F | L | W (KG) |

| D9-610 | 24.1 | 33 | 7.94 | 50.8 | 41.28 | 9.53 | 610 | 6.6 |

| D10-610 | 28.58 | 38.1 | 14.29 | 66.68 | 57.15 | 9.53 | 610 | 10.4 |