#704,No.2362,Fangzhong Road,Xiamen,Fujian,China,361009 +86-18350098686 [email protected]

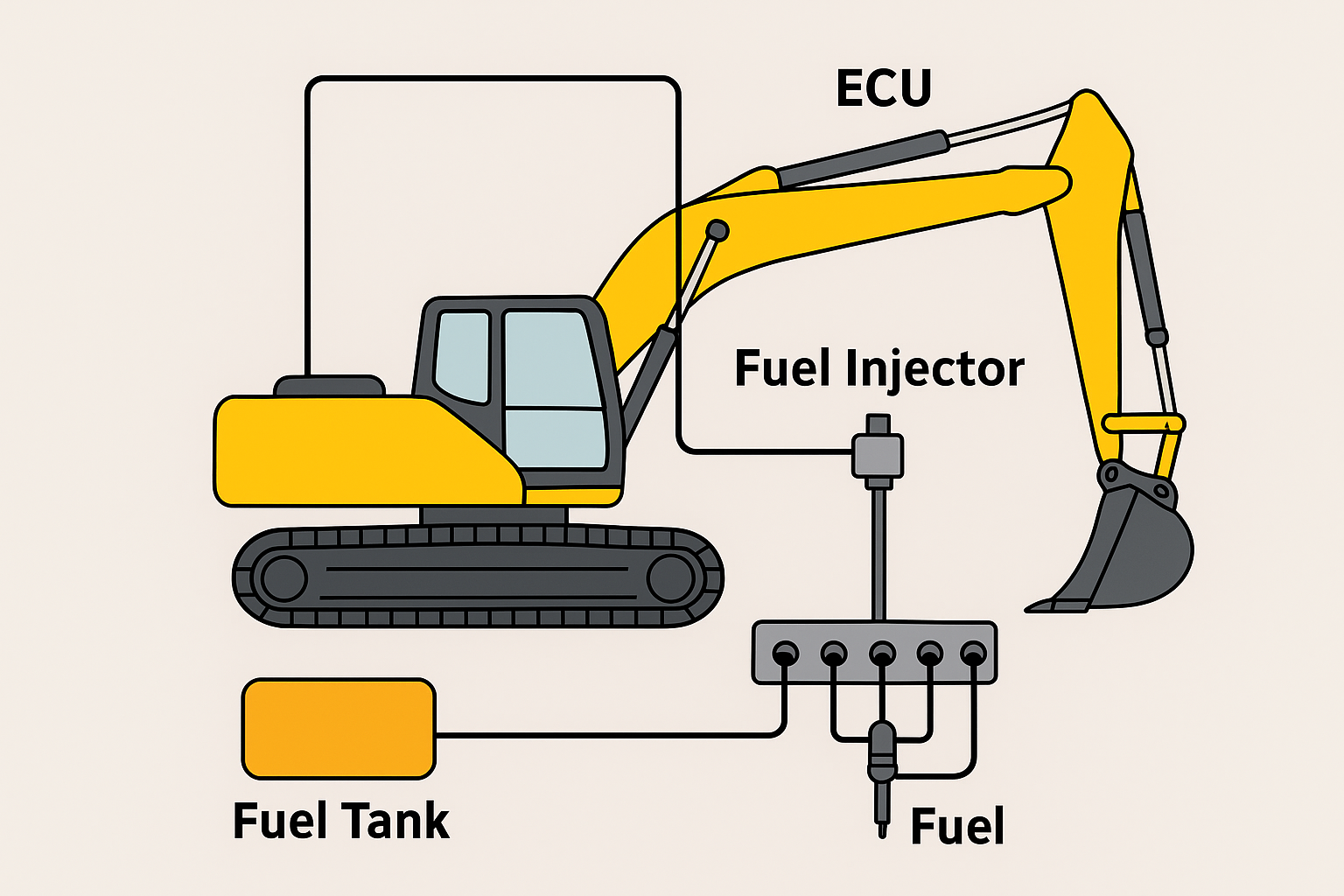

The fuel injector plays a decisive role in ensuring that construction machinery engines operate efficiently, cleanly, and reliably under varying working conditions. Its functions extend beyond simple fuel delivery and cover precision control, energy optimization, and emission reduction.

I. Precise Fuel Metering

The injector delivers the exact amount of fuel required by the engine at any given moment. This precision helps maintain the ideal air–fuel ratio, ensuring optimal combustion and consistent power output.

II. High-Pressure Atomization

By spraying fuel at extremely high pressure, the injector atomizes it into ultra-fine particles. This maximizes the contact area between fuel and air, improving combustion speed and efficiency.

III. Dynamic Response Control

During rapid changes in engine load—such as acceleration, heavy lifting, or braking—the injector instantly adjusts fuel delivery. This guarantees smooth engine response and stable power output.

IV. Energy Efficiency and Fuel Economy

Accurate injection timing and quantity reduce unnecessary fuel consumption, helping construction machinery maintain high efficiency during prolonged operation.

V. Emission Reduction and Environmental Protection

Optimized fuel atomization and combustion reduce the generation of soot, CO, and unburned hydrocarbons. Modern injectors work with electronic control systems to meet stringent emission standards.

VI. Engine Protection and Reliability

Consistent fuel delivery prevents knocking, overheating, and carbon buildup—extending the service life of key engine components and improving overall system reliability.